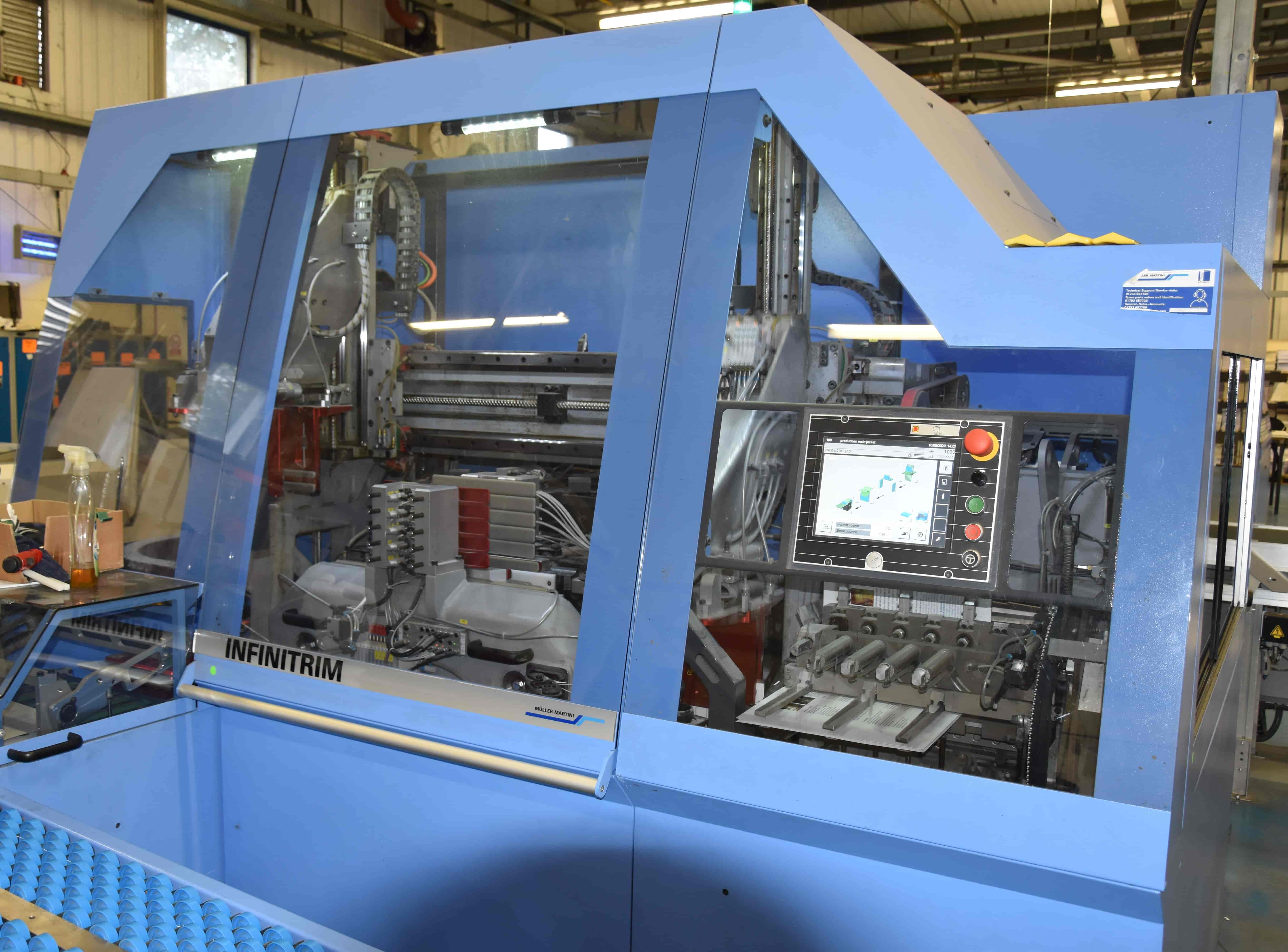

In order to be able to process the increasing volume of digital printing, TJ Books in the English coastal town of Padstow (county of Cornwall) invested in two Vareos. One of the two Muller Martini perfect binders is linked to an end sheet feeder for the production of hardcover book blocks. And from both, the books lead into a three-knife robot InfiniTrim.

Founded exactly 50 years ago by Tom Jacks and employing 142 people in a six-day/four-shift operation, TJ Books was quick to recognize the new trends in the graphic arts industry. That's because it entered the digital printing business back in the late 1990s. "The experience we have in this segment is therefore correspondingly great," emphasizes Co-Owner and Managing Director Andy Watts. He bought the company in 2017 together with Andy Adams, who acts as Finance Director.

Digital printing: 30 percent volume – 45 percent sales

The importance of digital printing has grown steadily in recent years. Today, for example, TJ Books has three offset sheetfed presses as well as three each of toner and inkjet digital presses. Almost 30 percent of the volume is printed digitally. In terms of sales digital printing accounts for as much as 45 percent.

In addition to softcover and thread sewing, TJ Books' core business is the production of classic hardcover books, particularly in short runs. Of the 6.5 million books printed each year, mainly for publishers throughout the UK, but increasingly also for self-publishers, the print run per title is 1,400 in offset, but only 170 in digital and as little as 1.5 in print on demand. A successful business model in the B2C sector is also books with a print run of 1. If a customer leaves it open as to which printing process is to be used, TJ Books makes the decision itself as to whether offset or digital is to be used.

Andy Watts (left), Co-Owner and Managing Director of TJ Books, in front of the Vareo perfect binder in Padstow: "We won back orders we'd lost because we weren't cost-effective enough before." Right, David McGinlay, Sales Manager Muller Martini United Kingdom).

Two Vareos – one InfiniTrim

Andy Watts (left), Co-Owner and Managing Director of TJ Books, in front of the Vareo perfect binder in Padstow: "We won back orders we'd lost because we weren't cost-effective enough before." Right, David McGinlay, Sales Manager Muller Martini United Kingdom).

Two Vareos – one InfiniTrim

The continuously increasing digital output – black and white as well as color – thanks to major technological advances and new possibilities, naturally also has an impact on postpress. "I consider finishing to be more important than printing," says Andy Watts. That's why, in addition to a BF 530 hardcover bookline and a KM 600 perfect binder, TJ Books relies on two Vareos from Muller Martini – one as a solo machine with hotmelt gluing and one with hotmelt and PUR and coupled with an end sheet feeder for the industrial production of short-run hardcover book blocks. From both perfect binders, the books go into an InfiniTrim three-knife trimmer.

According to Andy Watts, the two Vareos bring his company several advantages: "We have a faster workflow, less manual intervention and less waste – nowadays a not insignificant ecological argument. In addition, the Vareo is very user-friendly, so an even less experienced machine operator can quickly get to grips with it. On balance, we doubled productivity in print-on-demand – including printing. And we won back jobs that we had lost because we were not cost-efficient enough in the past. We are therefore extremely happy with the two Vareo."

"Passionate about Print"

Andy Watts is convinced "that the importance of digital printing will continue to grow, especially in terms of longer runs." He is therefore confident about the future: "That shorter time windows and environmental considerations ('print locally') will become increasingly important, i.e. for on-demand printing. But we have to be able to react quickly and flexibly and, true to our company slogan 'Passionate about Print', we want to stand out from the competition with high-quality books."

Read more about the end sheet feeder/Vareo/InfiniTrim inline-trio in this blog on the Muller Martini website.

Books from both Vareo perfect binders go into an InfiniTrim three-knife trimmer.

Books from both Vareo perfect binders go into an InfiniTrim three-knife trimmer.