The Kyburz AG printing house in Dielsdorf, just outside Zurich, which specializes in mailings, invested in two new Primera PRO saddle stitchers from Muller Martini. The Swiss company, which is active throughout Europe, is thus reacting to the smaller print runs and more variable size products in its core business.

For eight years,

Kyburz AG relied on two Muller Martini Primera E140 saddle stitchers of different lengths in two-shift operation – one with eight, the other with four feeders. "In the medium term, a retrofit with greater service requirements was an obvious choice," says Patrick Kyburz, CEO. Together with his father Koni Kyburz, who founded the company in 1972, he therefore evaluated a new solution.

"We looked around the market thoroughly and looked at various systems," says Patrick Kyburz. Naturally, Muller Martini had a certain home advantage due to our many years of good experience. And so, the request to act as a pilot customer for the newly launched

Primera PRO came at just the right time.

High format variability

For several months, Kyburz AG put the two new saddle stitchers – the long one with cover feeder, eight feeders and center cut equipment, the short one with cover feeder, four feeders and center cut equipment, plus a product gluer and a Robusto stacker – through their paces. It was an exciting time, as Patrick Kyburz emphasizes: "The cooperation between the two companies worked perfectly and Muller Martini took on board many of our suggestions.”

One of the greatest strengths of the new Primera PRO is its high level of size variability. For Kyburz AG, which specializes in personalized mailings, self-mailers, individualized leaflets, brochures and flyers, this is an extremely important aspect "because we have many special products" (Patrick Kyburz).

However, these are not only becoming more variable, but also increasingly have smaller print runs between 500 and 2500 copies. And that's where the Primera PRO with its advanced servo technology plays an additional plus point – its short changeover time. According to Patrick Kyburz, the faster makeready, together with the high level of production reliability, ensures "a significantly higher net output than the two previous models.

"The weakest link determines the cycle"

The fact that his two new saddle stitchers not only run quietly but also reliably is an important cornerstone of success for the CEO: "With complex products, it is always the weakest link that determines the pace. That's why everything must be just right with a saddle stitcher – from the feeder to the three-knife trimmer. Keyword three-knife trimmer: This was completely newly developed by Muller Martini for the Primera PRO. It is fully variable in thickness and adjusts itself for each product.

Patrick Kyburz is convinced that his company has further strengthened its market position with the two 14,000 cycle saddle stitchers and the new Xerox Versant 180 digital printing press with integrated finishing, which was also commissioned this year. "This is what we are basing our new investment on.

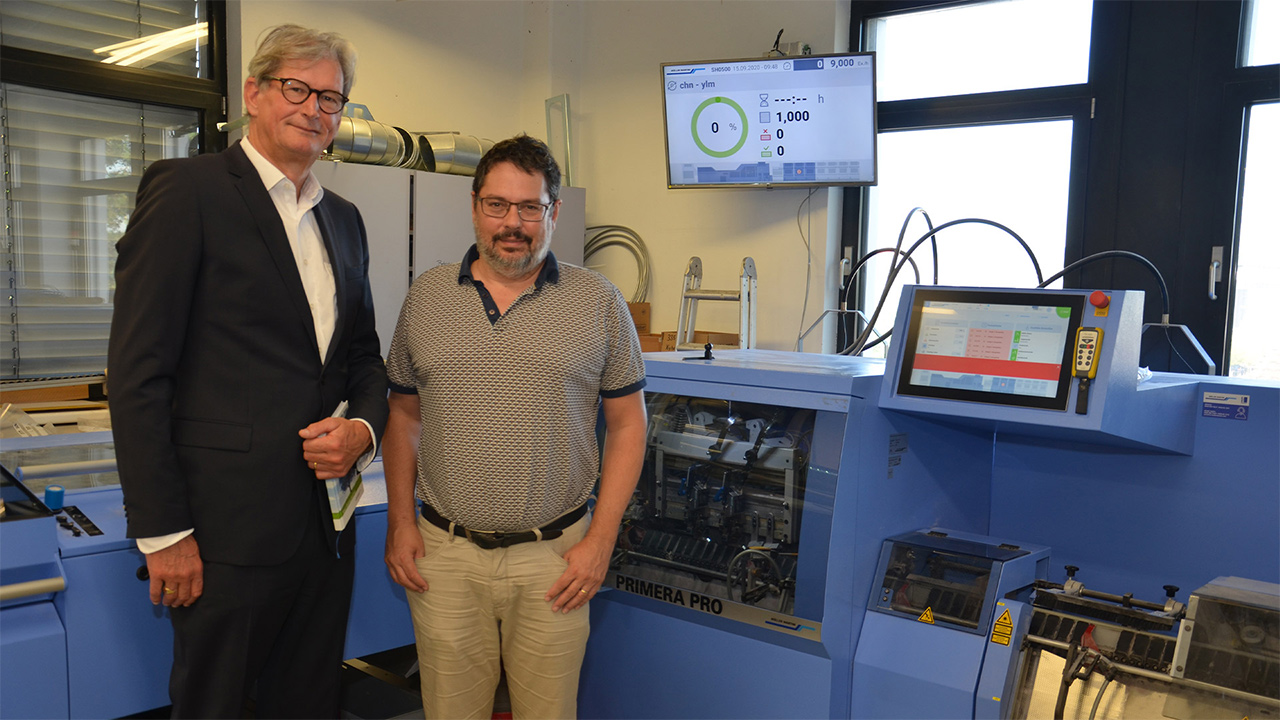

Patrick Kyburz (right), Chief Executive Officer: "In a high-wage country like Switzerland, we need new technological solutions in order to produce cost-effectively". Left Richard Hofer, Sales Manager Muller Martini.

New technological solutions for cost-effective production

Patrick Kyburz (right), Chief Executive Officer: "In a high-wage country like Switzerland, we need new technological solutions in order to produce cost-effectively". Left Richard Hofer, Sales Manager Muller Martini.

New technological solutions for cost-effective production

Kyburz AG, which employs 135 people, is one of the few graphics companies in Europe that specializes in such

mailing products. It supplies customers not only in its main market Switzerland, but also in several European countries – for Germany often with runs of several million. "However, this is only possible if the price-performance ratio is right. In the end, it's almost always about the price. And that's why we need new technological solutions – especially in a high-wage country like Switzerland – to produce cost-effectively," emphasizes Patrick Kyburz.

One of the secrets of his success has been close cooperation with advertising agencies for years. "They show us their ideas. In discussions between the creatives and our production experts, we then find out what can be produced, what is affordable and what can be sent by post.

Kyburz AG has not only made a name for itself with innovative print products and optimal address management, but also with its commitment to the environment. Thus, thermal afterburning, heat exchangers with piping and control systems produce surplus heat, which corresponds to 51,000 litres of fuel oil and is made available free of charge to the neighbouring sports facility Erlen. The use of natural gas instead of propane gas also reduces the company's CO

2 emissions by 15 percent.

Successful field test: Walter Kägi (left) from Kyburz AG and Michel Müller from Muller Martini talk shop about the completely redesigned three-knife trimmer of the Primera PRO saddle stitcher.

Successful field test: Walter Kägi (left) from Kyburz AG and Michel Müller from Muller Martini talk shop about the completely redesigned three-knife trimmer of the Primera PRO saddle stitcher.