Funke: Two new ProLiners handle the significantly higher insert volume

04/12/2017

Two further ProLiner newspaper inserting systems are set to replace three 25-year-old Biliners – Funke Druck GmbH is responding to its continuing growth in inserts by modernizing the mailroom at its printing center in the city of Erfurt in the German state of Thuringia.

Funke produces three of its own daily newspapers with 35 different zoned editions and a total circulation of 275,000 copies, as well as three of its own advertising papers with a weekly circulation of 2.43 million copies at its printing center in Erfurt. Dr. Klemens Berktold, Managing Director of Funke Druck GmbH, which operates four printing centers in the German cities of Essen, Hagen, Braunschweig and Erfurt, explains that “newspapers, and in particular advertising papers, remain popular as carriers for inserts.” In recent years, the insert volume at the company in Erfurt has grown by some three percent on average. In addition two particular factors have resulted in additional growth in the recent past, namely the introduction of the minimum wage and, second, expansion of the advertising paper business.

In seven months’ time, Funke Druck GmbH will have four ProLiner newspaper inserting systems at its printing center in Erfurt.

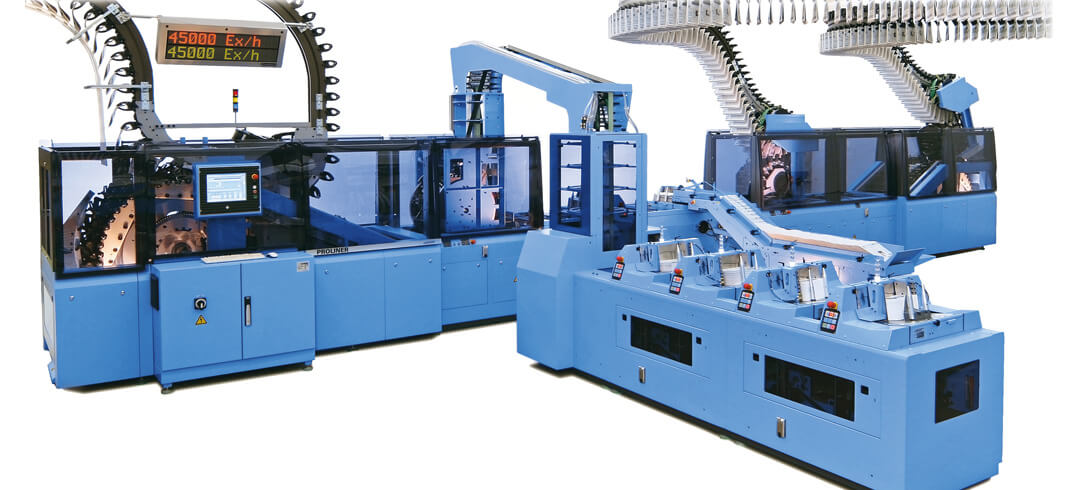

The investment that has now been decided will complete the modernization of the mailroom that began a few years ago. The mailroom will be equipped with a total of four ProLiners. A CoLiner pre-gathering system will be integrated with two of those ProLiners. The mailroom lines, with up to 22 stations and new MiniFeeders, will each be equipped with three FlexPack bundle building systems with an integrated top-sheet printing unit and the Connex.Mailroom control system.

The newspaper publishing house is aiming to further reduce the proportion of manual work when it comes to complex, zoned inserts. According to Dr. Klemens Berktold, Funke Druck performed a thorough evaluation of the new newspaper inserting systems. “Synergy effects based on our two existing ProLiners played an important part in our decision to invest in a Muller Martini solution again.”