Three performance classes

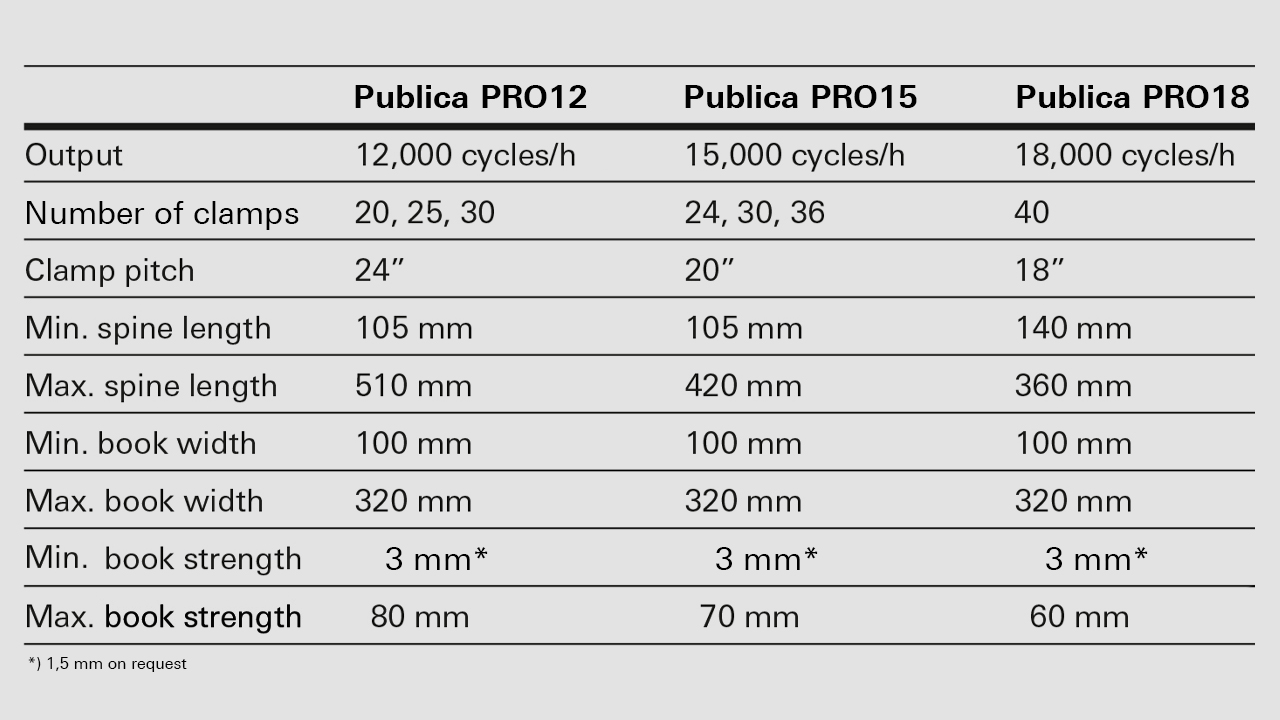

The perfect binding line, which is ideal for magazines, catalogs and high-volume publications, is available in three performance classes: 12,000, 15,000 and 18,000 cycles per hour (see graphic). The 12,000-cycle version can also be used to produce hardcover book blocks and spine strengthening is possible by using a lining station.

The Publica PRO, which is predestinated for single sheets and thin print runs, demonstrates its full flexibility with the ZU 842 suction-belt gathering machine, which has an output of 18,000 cycles per hour. It pulls off in the direction of material flow so that there is no wear and tear and separates the sheets via a suction belt in the running direction of the chain. The ZU 832 gathering machine (up to 12,000 c/h) is also available as an economical alternative.

Thanks to its modular design, the standard feeders up to 3 mm signature thickness (but extra feeders up to 5 mm are also possible as an option) can be easily replaced with a feeder for pre-folded signatures at the binding side or signatures with folded-in flaps as well as parallel folded or zigzag folded signatures that will be bound at their open side. The KK 842 card gluer processes a wide range of products (glued-in cards/booklets/CDs in covers /product samples). The electrostatic fixing of advertising media is also possible as an option.

The first Publica PRO is in production in Braunschweig – "Turn two into one"

Celebrating its 175th anniversary in 2020,

Westermann Druck GmbH recently invested in the world's first Publica PRO at its Braunschweig plant. The long-established German company is now concentrating on its two production sites – in Braunschweig and Zwickau – instead of three. Originally, Westermann Druck GmbH, which produces around 33 million softcover products annually with a focus on magazines, journals, catalogs and (school) books, planned to relocate a Muller Martini Corona perfect binder from the closed-down plant in Landau to Braunschweig (where 230 people are employed) and to produce on two lines there.

By means of a detailed business plan, however, we explained to our customer that a new investment in state-of-the-art technology is much more economical than operating two older lines. The slogan "Make one out of two" convinced the company, and so the choice fell on the Publica PRO15. In addition, an 18-station ZU 842 gathering machine was installed, while Westermann relied on existing (Muller Martini) systems for the peripherals.

What´s true for Westermann may well be true for many bookbinderies worldwide in my opinion: they often produce with older perfect binders with long make-ready and short cycle times. For them, "Make one out of two" is the right slogan – and the Publica PRO is the ideal solution.

Sincerely,

Your Lukas Budde

Product Manager at Muller Martini in Rahden