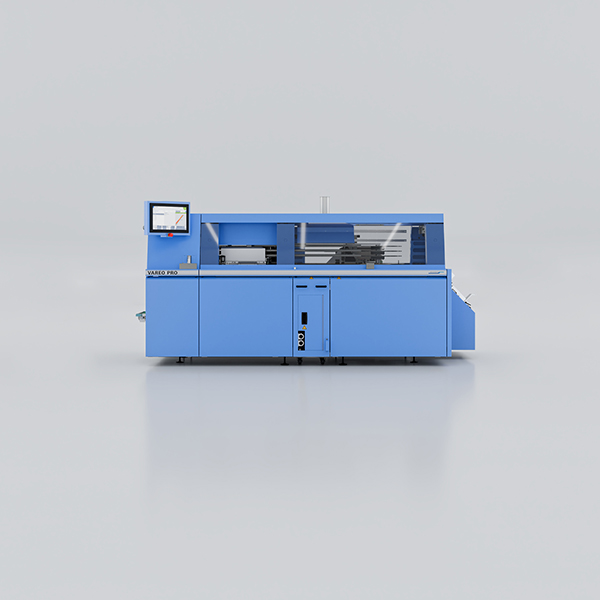

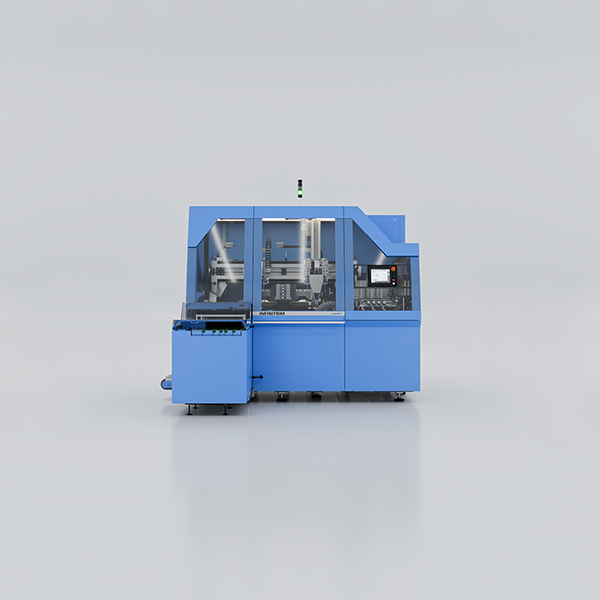

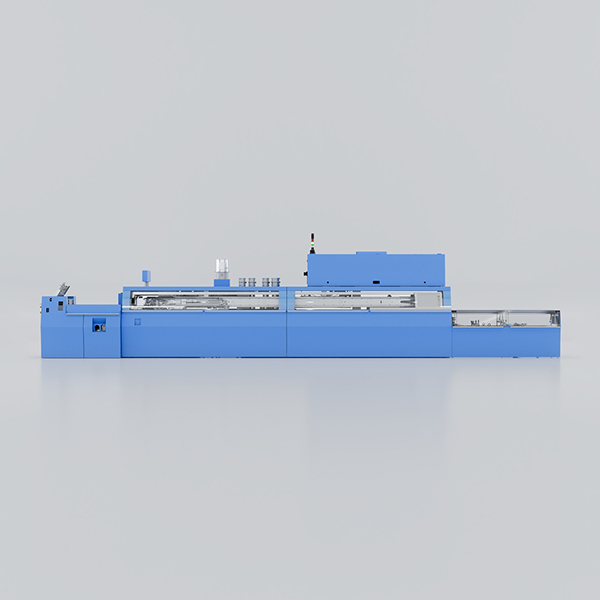

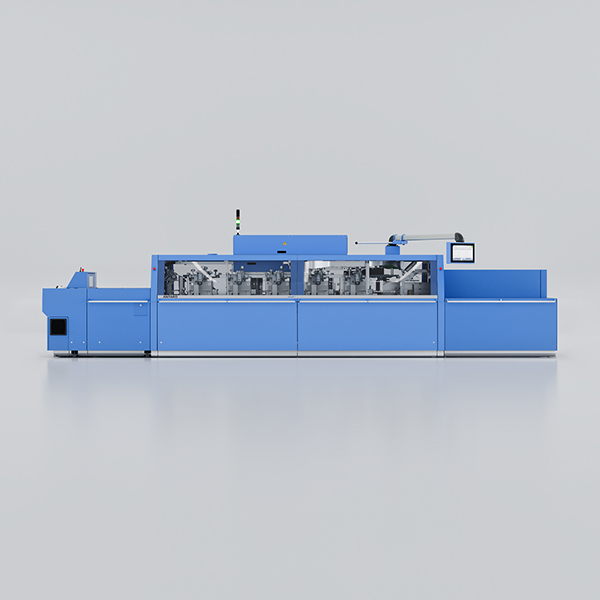

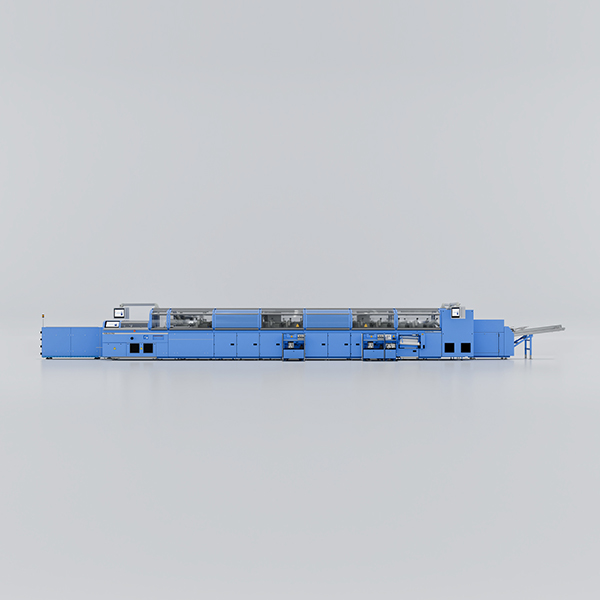

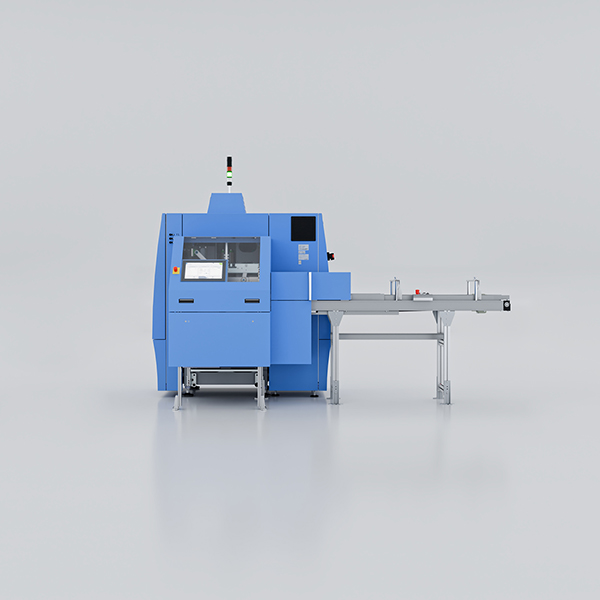

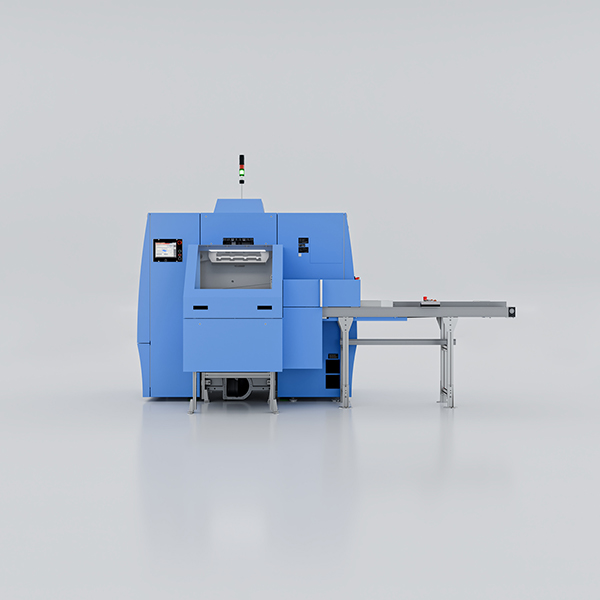

VBA 3683

For hardcover book blocks in edition 1 and in highest quality

The VBA 3683 is the most productive single book end sheet feeder on the market. It processes up to 1,000 books per hour – in both edition and single book mode. The attachment of continuous endpapers and hotmelt or PUR gluing ensure top-quality bound books. The VBA 3683 impresses with maximum flexibility: it can be used for all common book block types and has motorized adjustment of the distance from the endsheet fold to spine from 0 to 5 mm. In addition, it can be perfectly upgraded for future market requirements in terms of high investment protection – as a stand-alone or inline with the Vareo PRO HC.

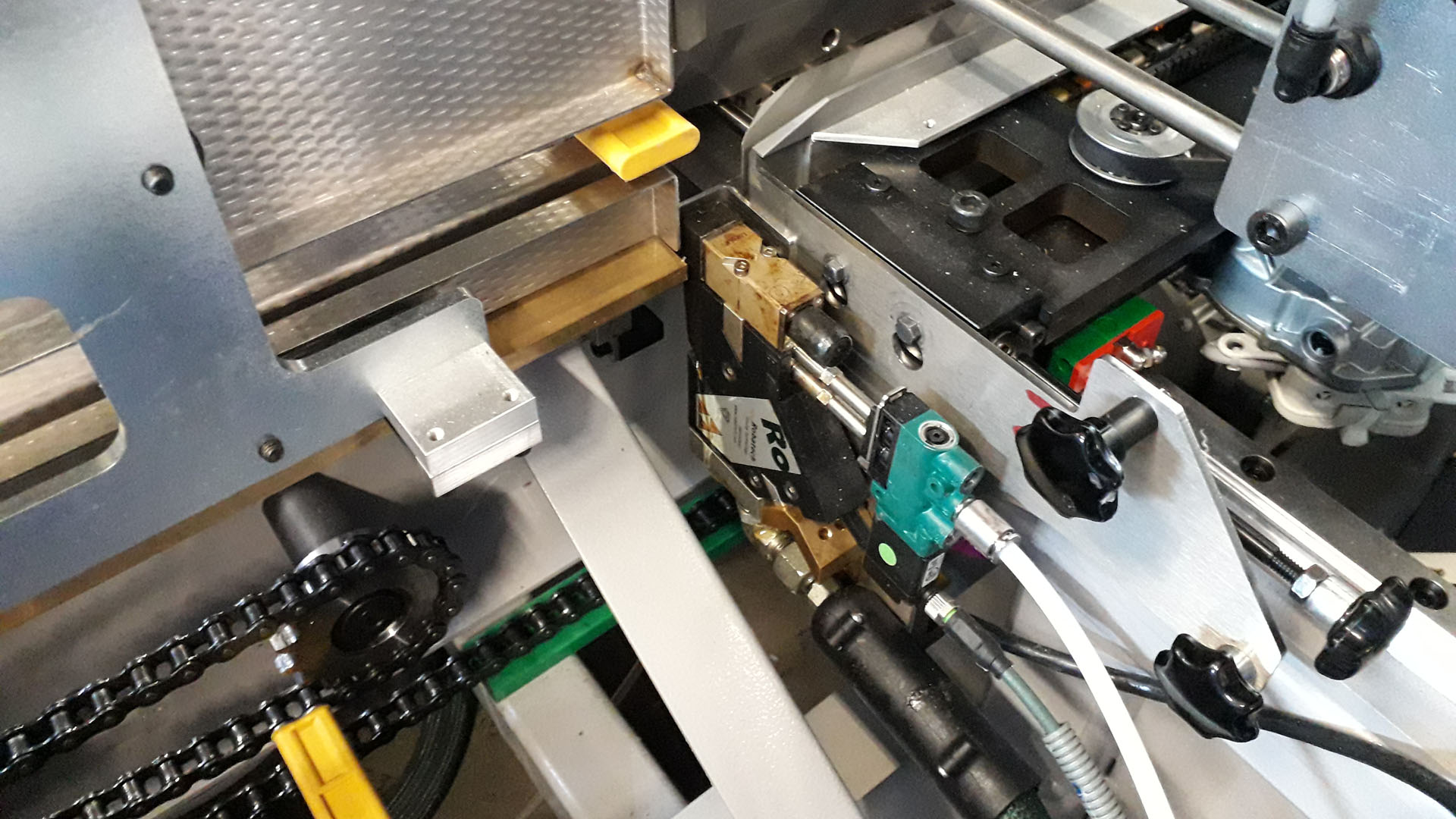

Compact process

Unique Operating Concept

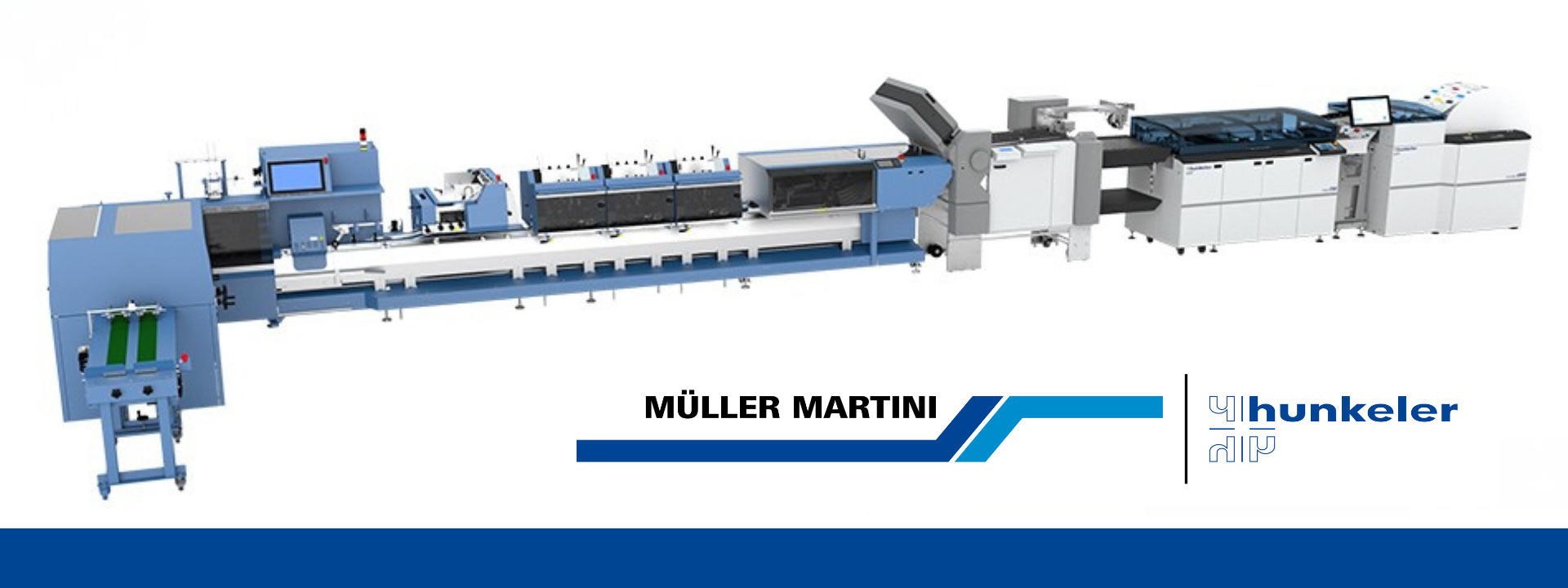

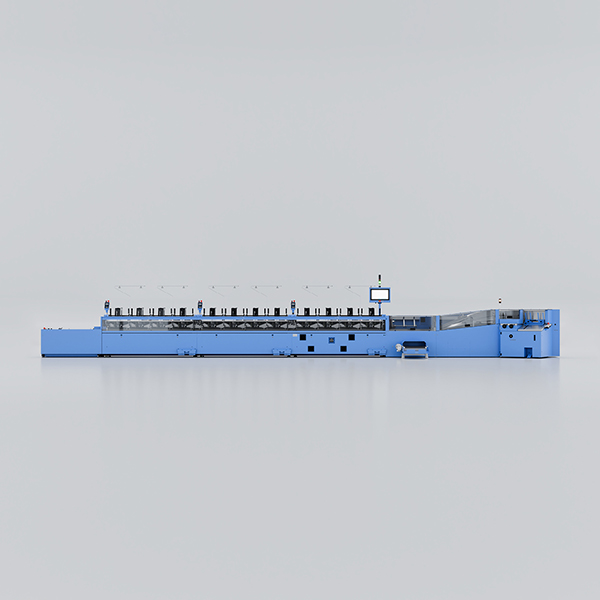

From the line to the cell

| Speed | 1’000 cycles/h |

| Format min. | 105 x 105 mm |

| Format max. | 360 x 330 mm |

| Thickness min. | 1.5 mm |

| Thickness max. | 60 mm |

| Endsheet paper grammage min. | 130 gsm |

| Endsheet paper grammage max. | 200 gsm |

Quick heads-up before you go

You’re about to open an external website (e.g. our virtual showroom or career portal). Please note that the privacy and cookie policies of that site apply, and we have no control over them.

If you’re okay with that, you can continue.