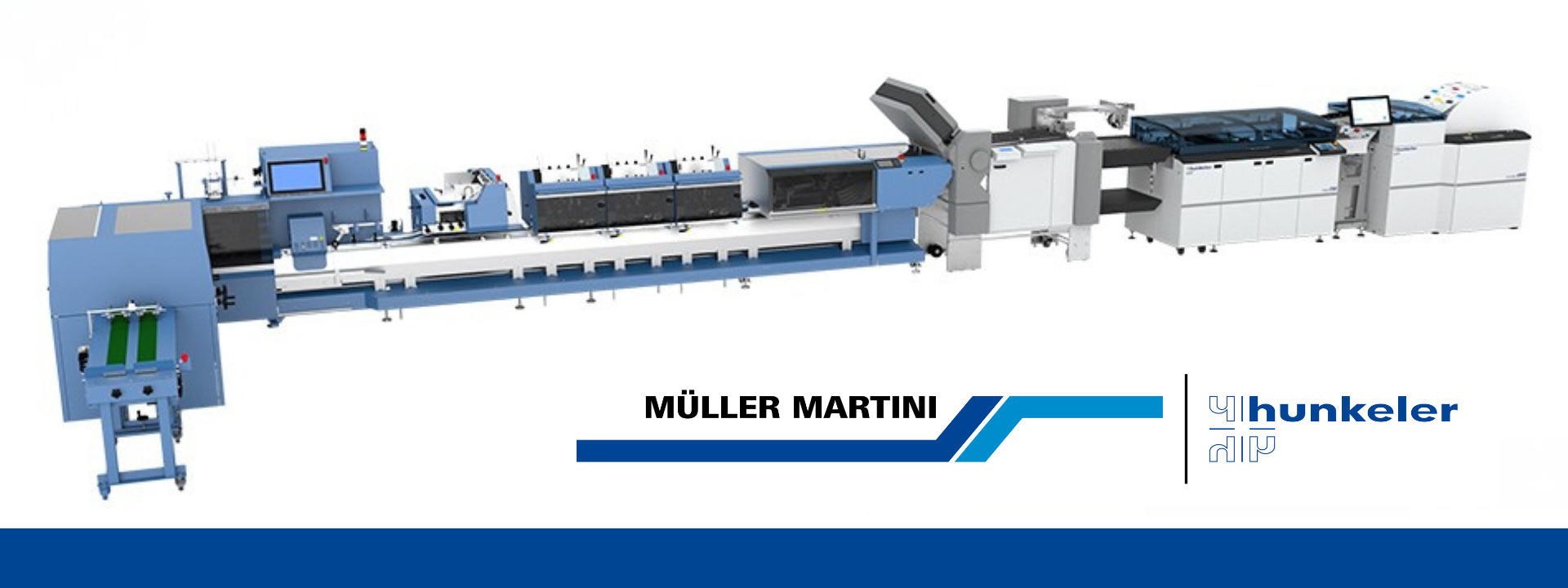

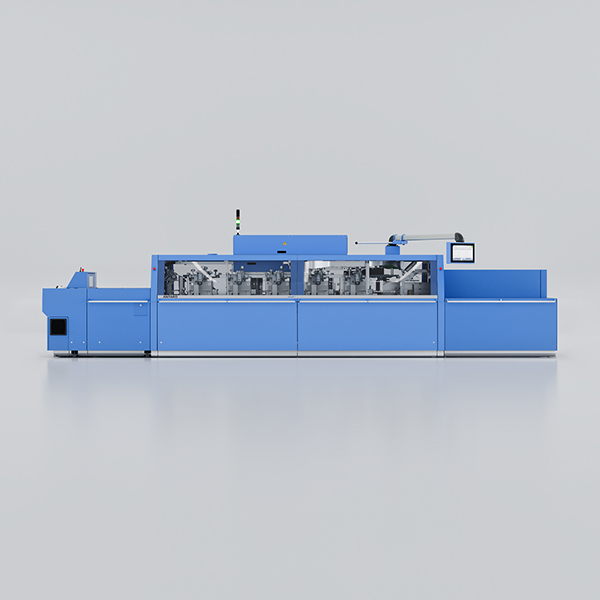

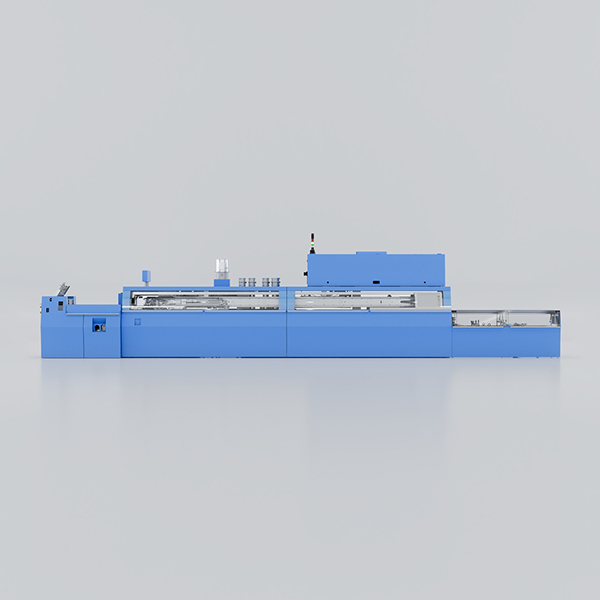

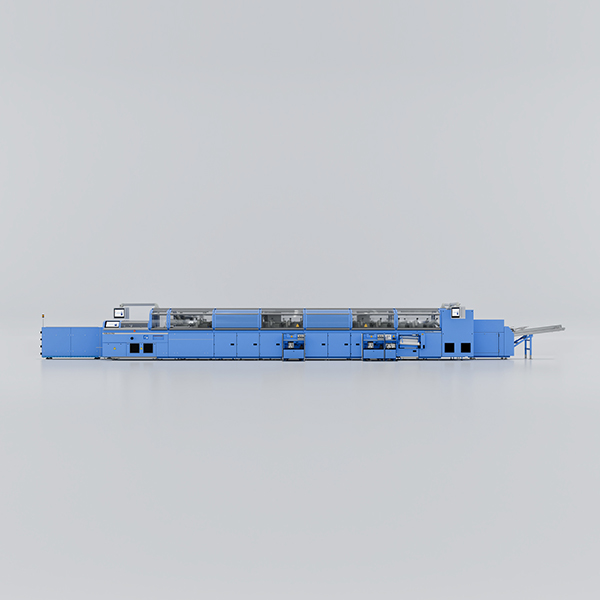

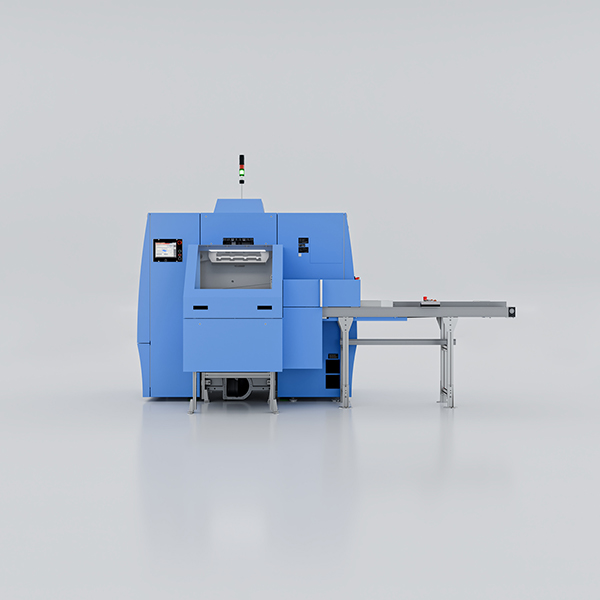

3502

First-Class Two-Up Production

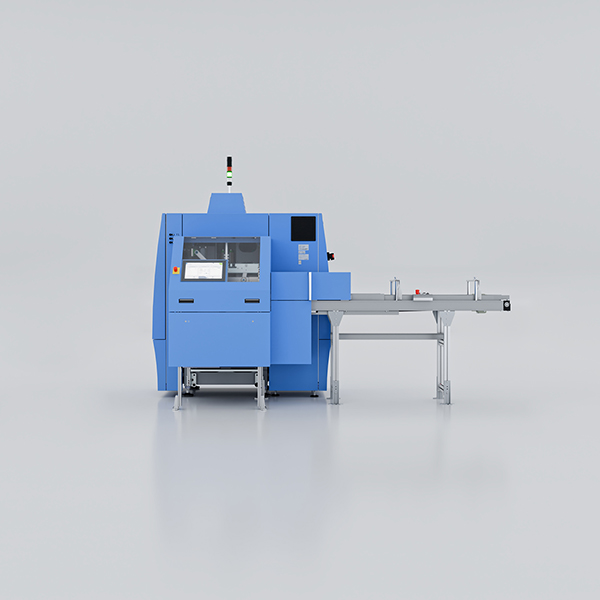

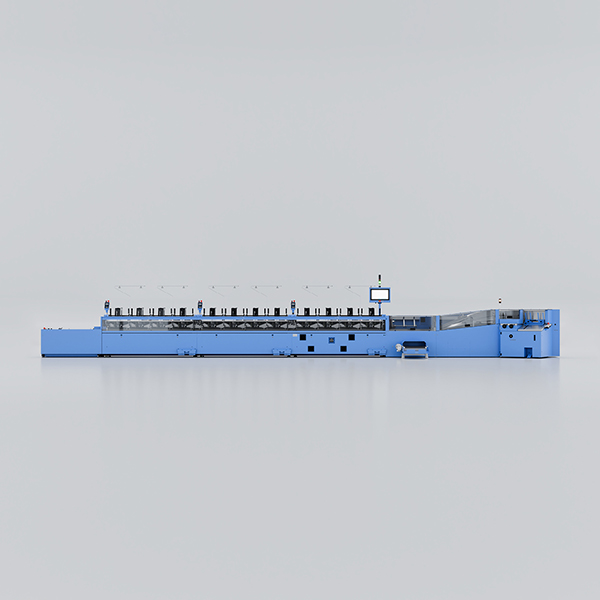

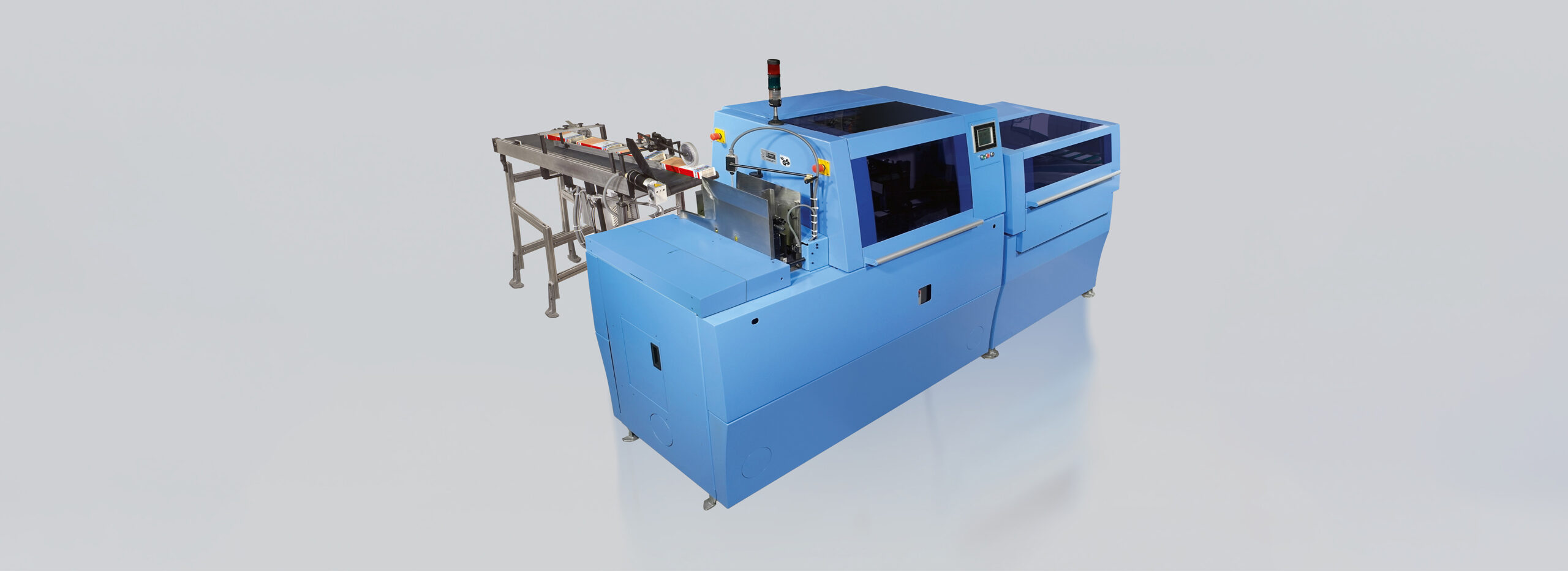

Two-up production considerably increases the capacity of the perfect binding line. For that bookbinders need systems that perform the separation step reliably and with a high output. The 3502 splitting saw cuts perfect-bound products extremely accurately. Thanks to full automation, the splitting saw can be quickly changed over without the need for tools. The siliconization of the saw blade guarantees a long lifetime and reduced maintenance costs.

Simple operation

The splitting saw can be changed over quickly, easily and without tools via the touch-screen.

Easy Integration

JDF data can be taken from a higher-level control system.

Store jobs

Another advantage is that data is stored and can be retrieved, which is ideal for repeat jobs.

| Speed | 15’000 cycles/h |

| Format uncut min. | 220 x 75 mm |

| Format uncut max. | 510 x 320 mm |

| Thickness min. | 1.8 mm |

| Thickness max. | 80 mm |

Quick heads-up before you go

You’re about to open an external website (e.g. our virtual showroom or career portal). Please note that the privacy and cookie policies of that site apply, and we have no control over them.

If you’re okay with that, you can continue.