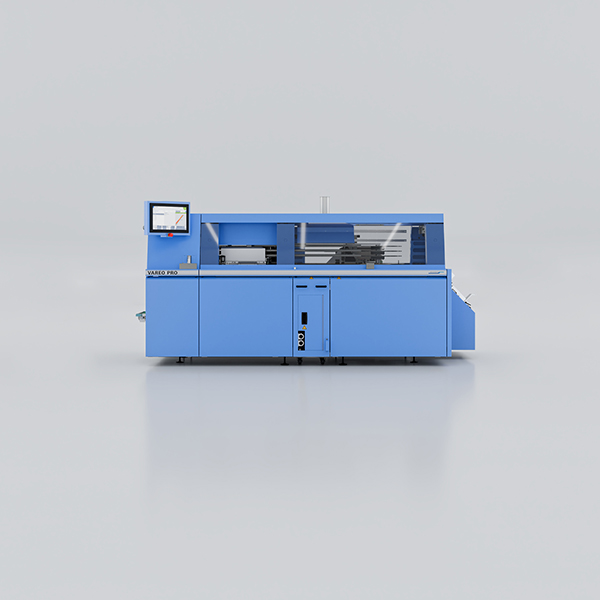

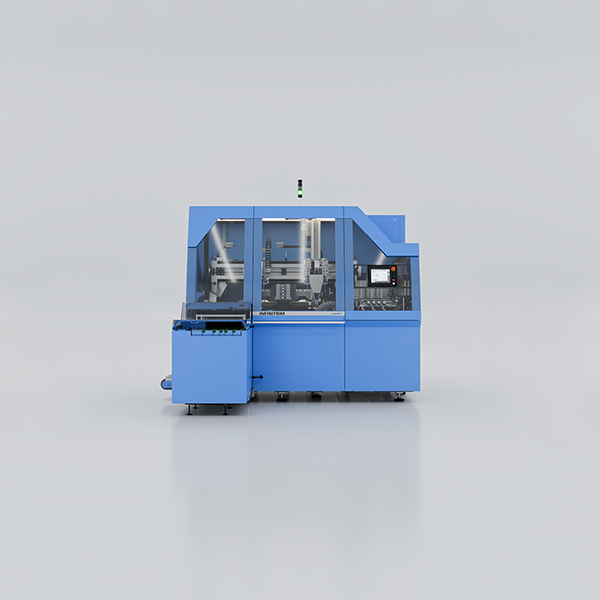

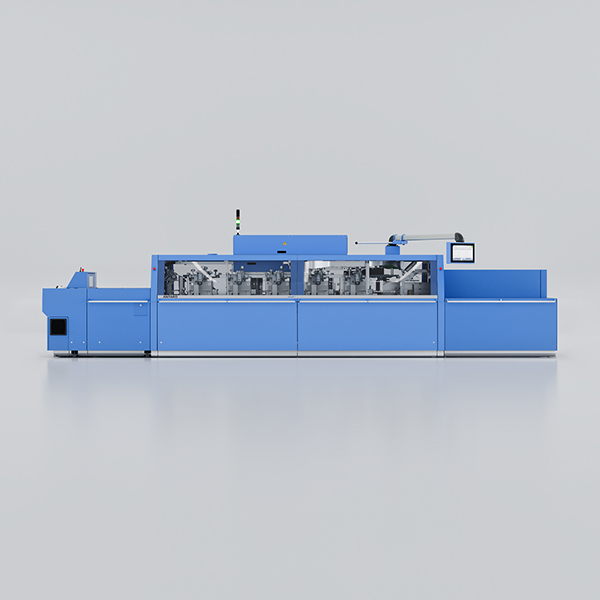

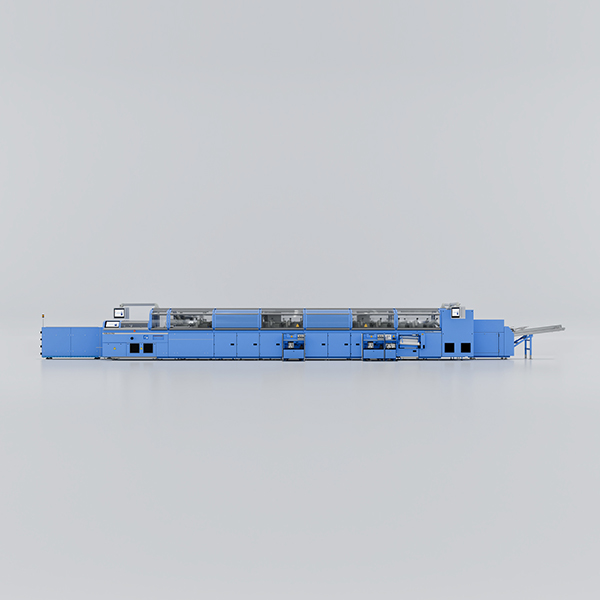

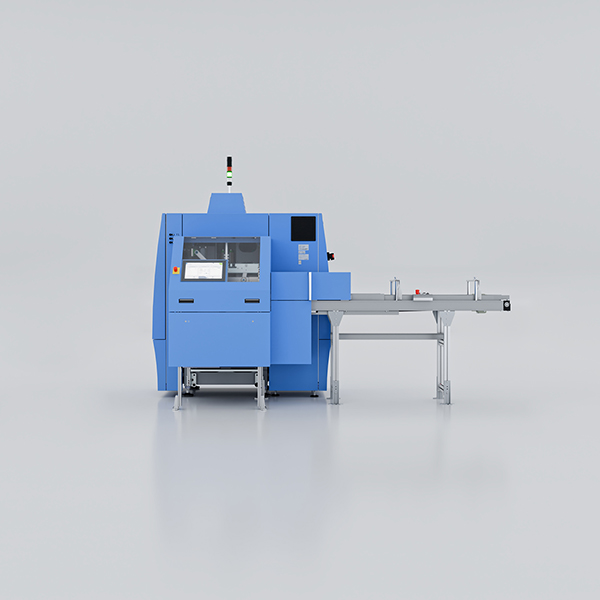

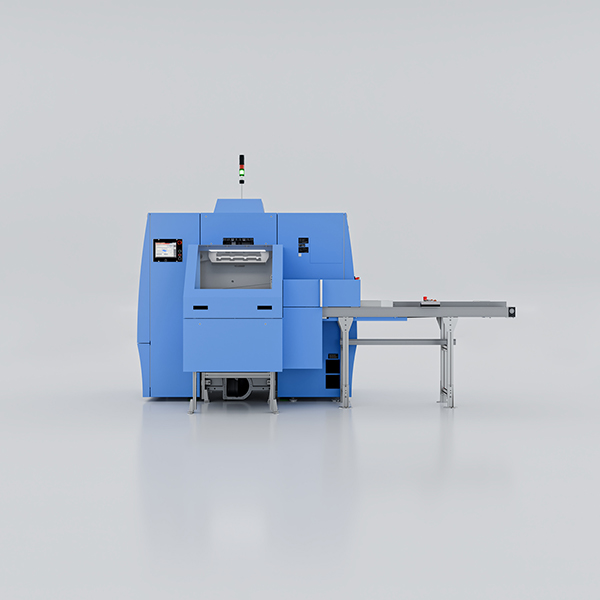

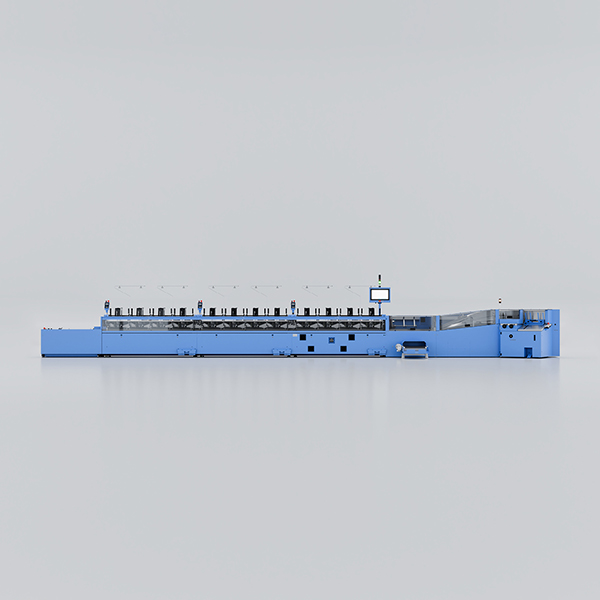

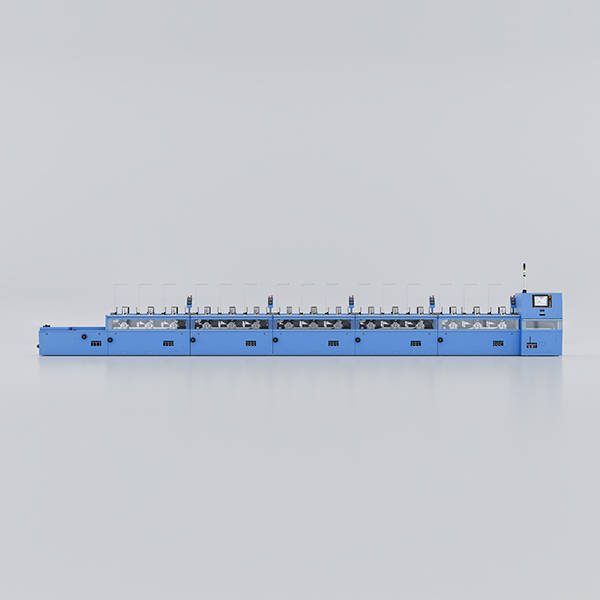

Alergro

For low production costs per book

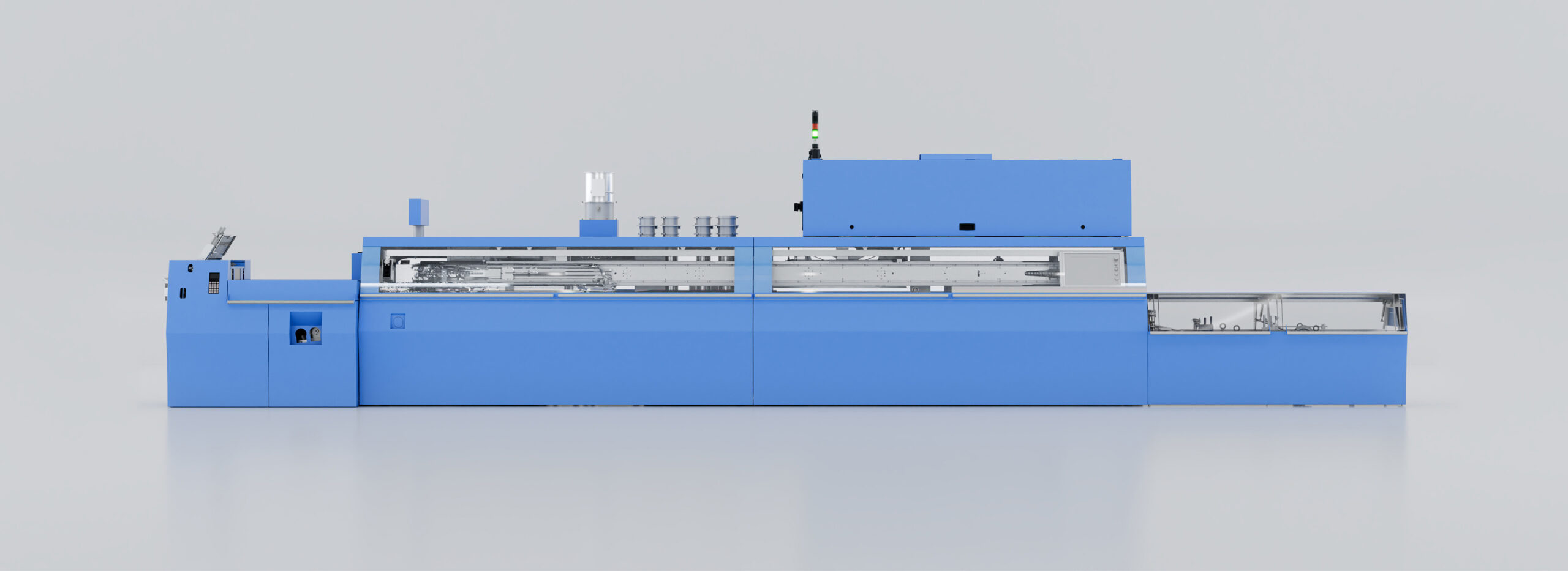

The Alegro counteracts the growing requirements in offset and digital printing with state-of-the-art drive and control technology – no matter the print volume. The ultra-flexible machine concept allows fast configuration changes and makes the perfect binder the ideal solution for production environments where requirements change almost on an hourly basis. Thanks to individual single drives, storable order data, and the option for integration with an end-to-end workflow system, the Alegro scores with extremely short order execution times. The result: unbeatably low production costs per book while also freeing up more capacities for new orders.

Short changeover times

Thanks to its high degree of automation, the Alegro stands out with short set-up times and production in record time at the highest level. All stations are driven directly and controlled individually. The settings can be reproduced, which directly impacts the accuracy of the products to guarantee outstanding book quality, even for repeat jobs.

Wide product range

The Alegro can process a huge range of sizes – from ultra-small to A3. A4 landscape products can be run in two-up production, which considerably reduces production costs for all print runs. It can produce books of varying thickness and with manual changeovers. The Alegro can be used for all conventional binding methods.

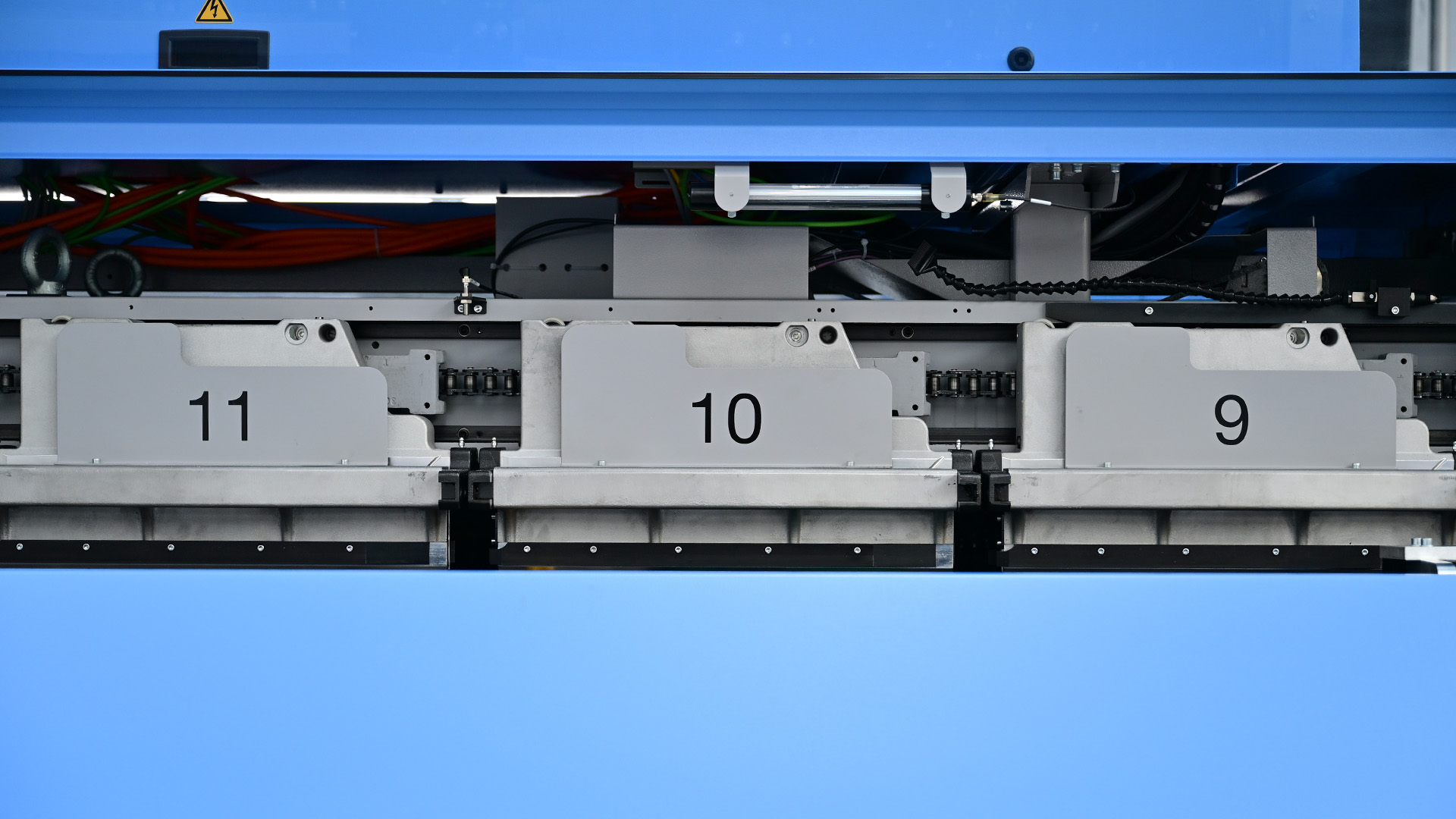

Low maintenance costs

By implementing separate drives, there is no need for shafts, gear boxes or chains to run the stations. That considerably reduces the need for lubrication and maintenance.

| Speed | 6,000 / 7,000 cycles/h |

| Format min. | 100 x 100 mm |

| Format max. | 480 x 320 mm |

| Thickness min. | 1 mm |

| Thickness max. | 65 mm |

| Grammage body paper min. | 28 gsm |

| Grammage body paper max. | 240 gsm |

| Grammage cover paper min. | 90 gsm |

| Grammage cover paper max. | 450 gsm |

Media center

Videos & Pictures

Quick heads-up before you go

You’re about to open an external website (e.g. our virtual showroom or career portal). Please note that the privacy and cookie policies of that site apply, and we have no control over them.

If you’re okay with that, you can continue.