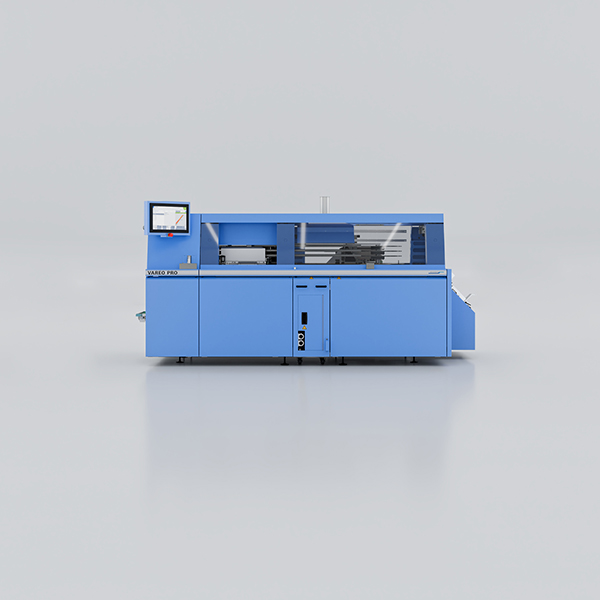

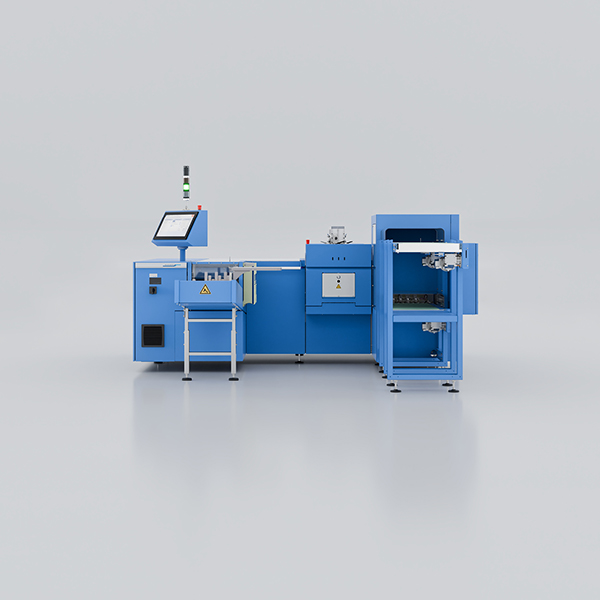

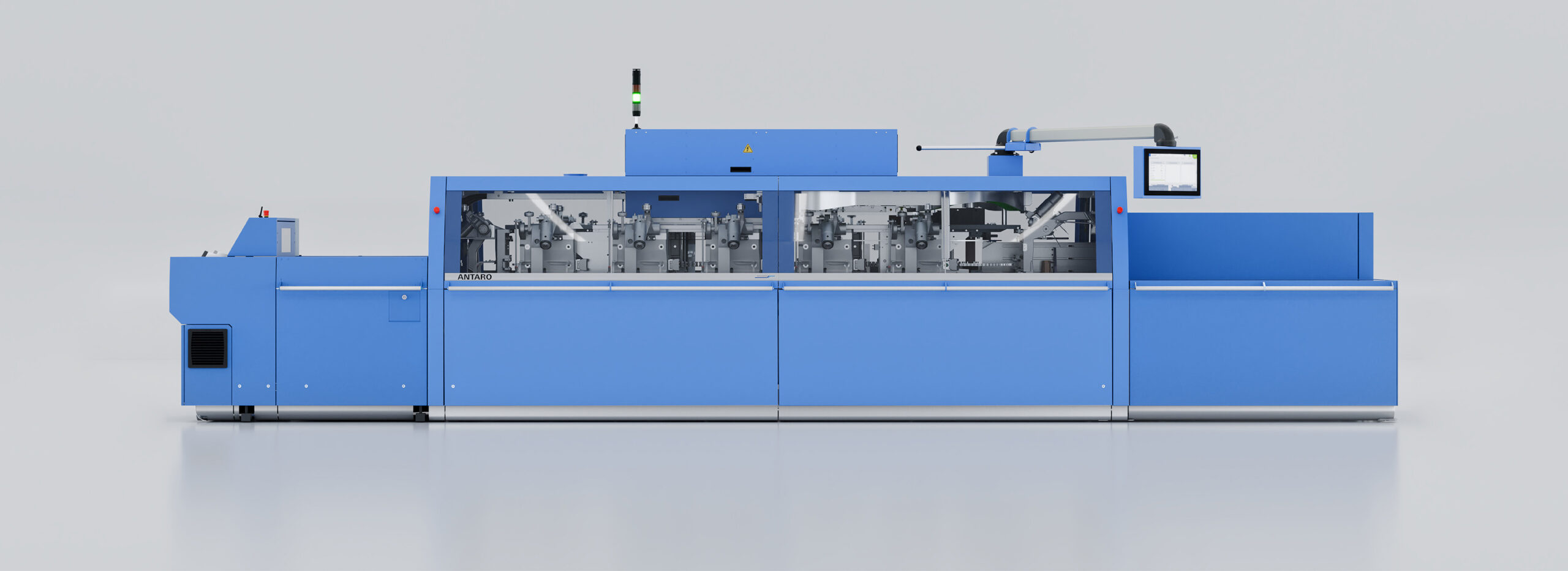

Antaro

Compact, flexible, future-proof

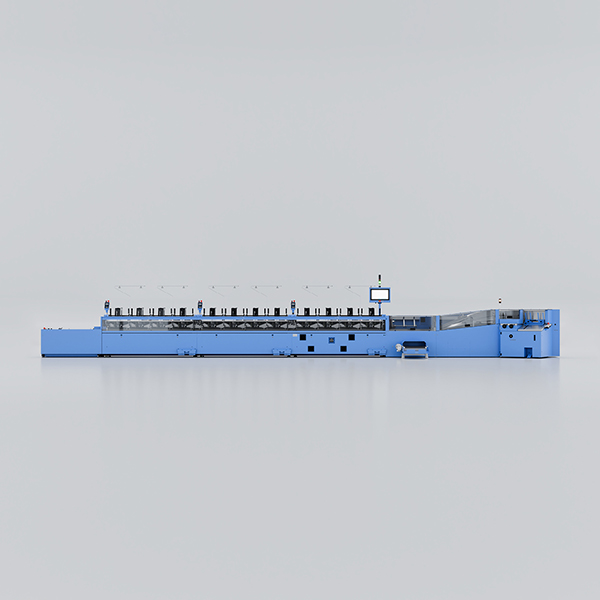

Combined with a gathering machine, a three-knife trimmer, and equipped with 12 staples, the Antaro is suitable for the production of offset jobs and achieves an output of 4000 cycles/hour. The Antaro perfect binder is not only very compact, but also extremely flexible in use: whether signature stacks, pre-glued or thread-stitched book blocks, or single-sheet stacks—the Antaro reliably processes all common types of book blocks. Thanks to its modular design, the system can be expanded at any time and adapted to new requirements. This is real investment protection for the future.

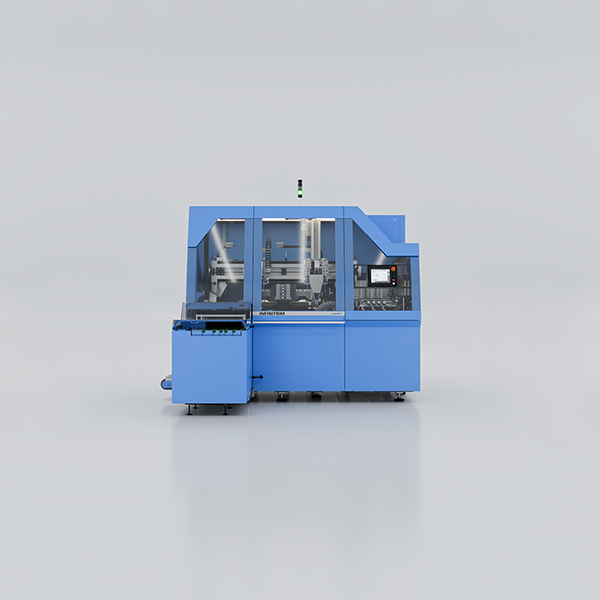

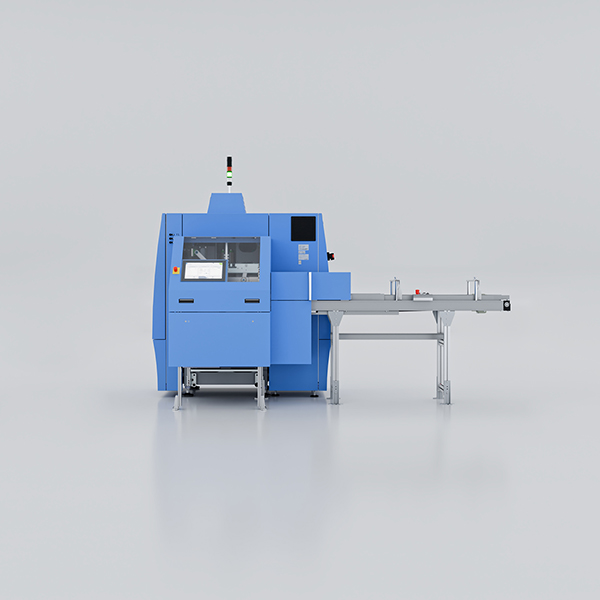

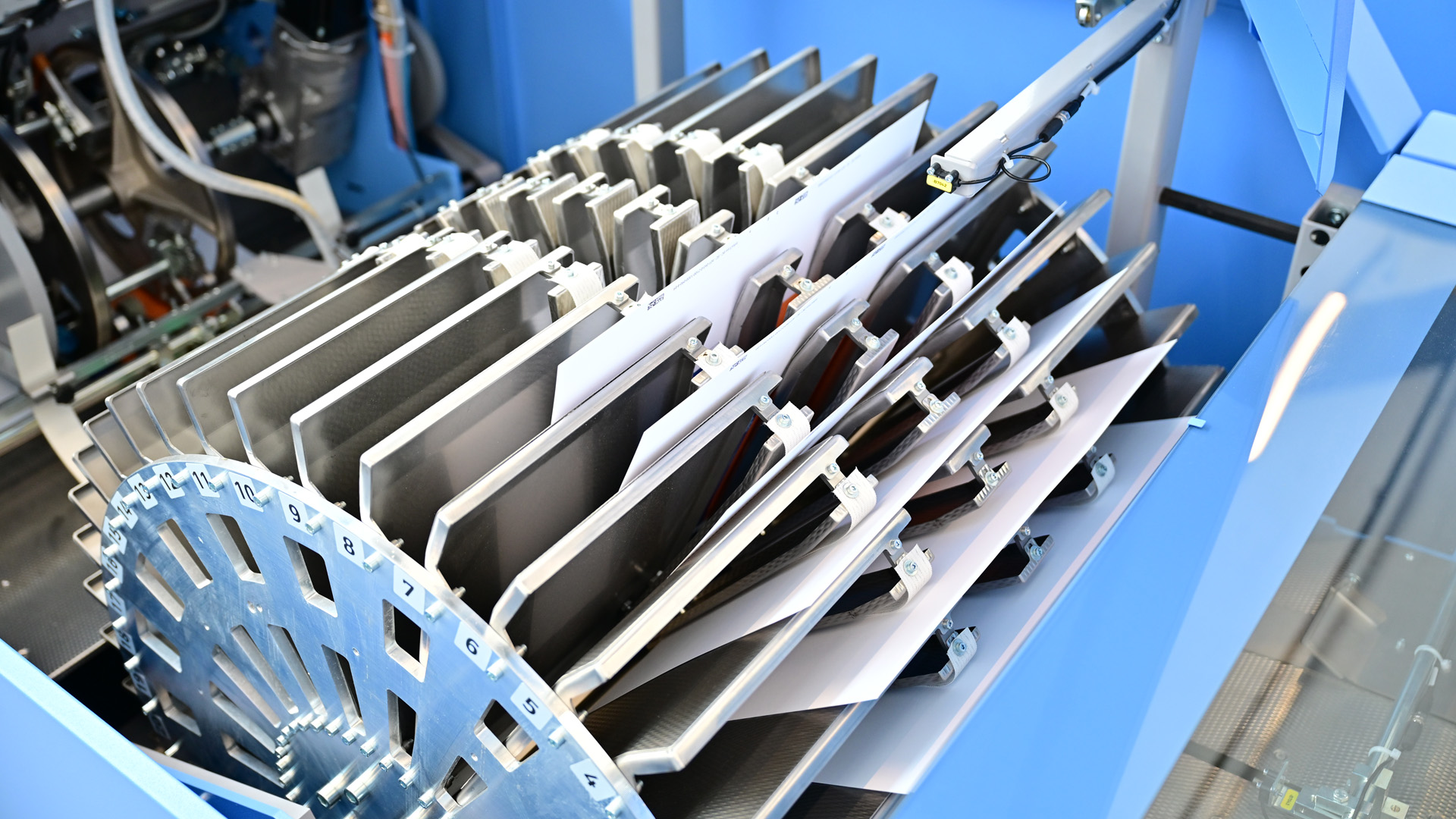

Highly automated

The Antaro produces with a continuously running swing clamp system. The book blocks are transported in horizontally, standing on their spines and are reliably retained by the clamps, which are always fully open.

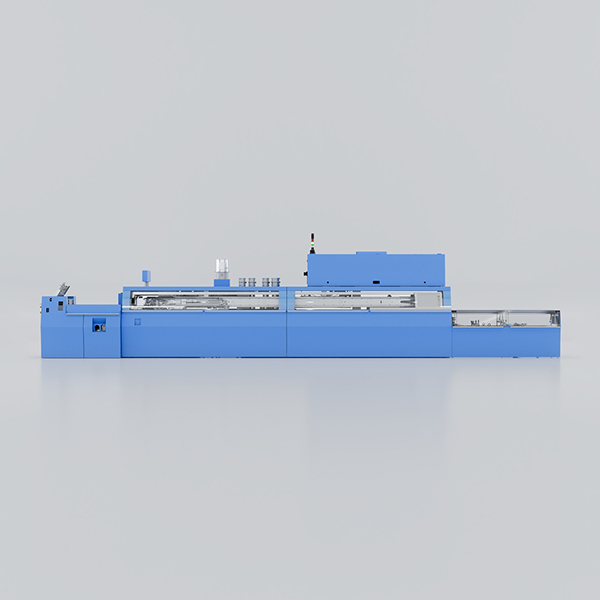

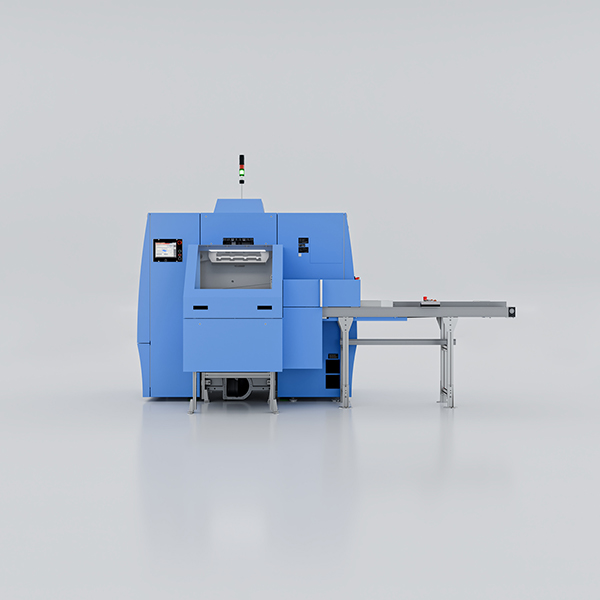

Top class end products

The perfect binder produces with two spine milling stations, therefore guaranteeing perfect spine machining. Replacing the gluing units is simple. The system uses EVA and PUR, as well as a glue monitoring system in the PUR nozzle, which controls correct application of the glue.

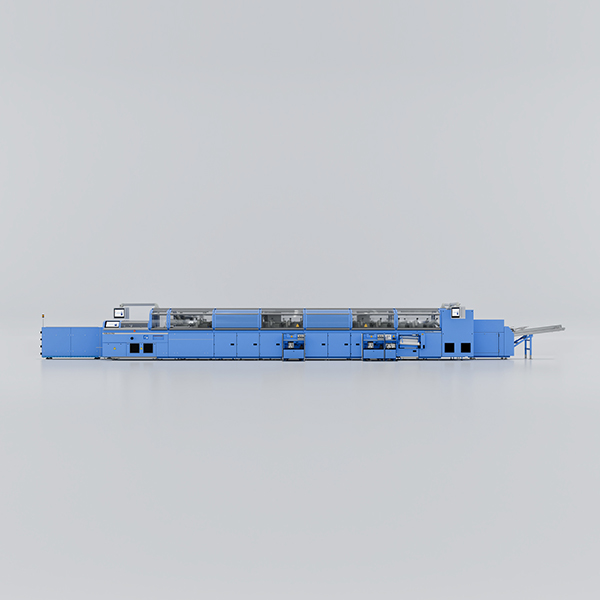

Unbeatable variability

The Antaro processes all conventional types of book blocks such as signature stacks, pre-glued or thread-sewn book blocks or single-sheet stacks, whereby these can be ergonomically and easily fed manually if no inline connection is available.

| Speed | 4,000 cycles/h |

| Format min. | 120 x 100 mm |

| Format max. | 380 x 320 mm |

| Thickness min. | 1.5 mm |

| Thickness max. | 60 mm |

| Grammage body paper min. | 60 gsm |

| Grammage body paper max. | 170 gsm |

| Grammage cover paper min. | 80 gsm |

| Grammage cover paper max. | 350 gsm |

Media center

Videos & Pictures

Quick heads-up before you go

You’re about to open an external website (e.g. our virtual showroom or career portal). Please note that the privacy and cookie policies of that site apply, and we have no control over them.

If you’re okay with that, you can continue.