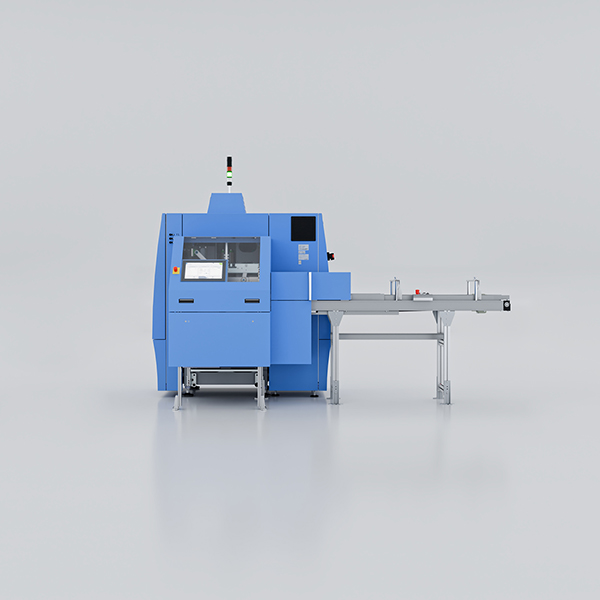

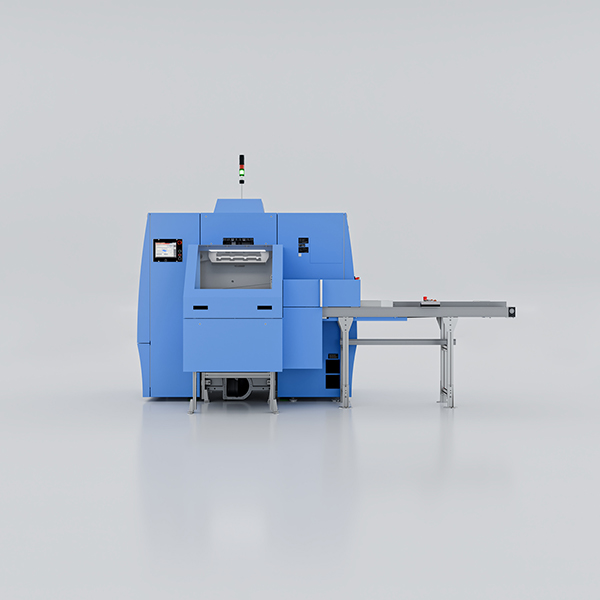

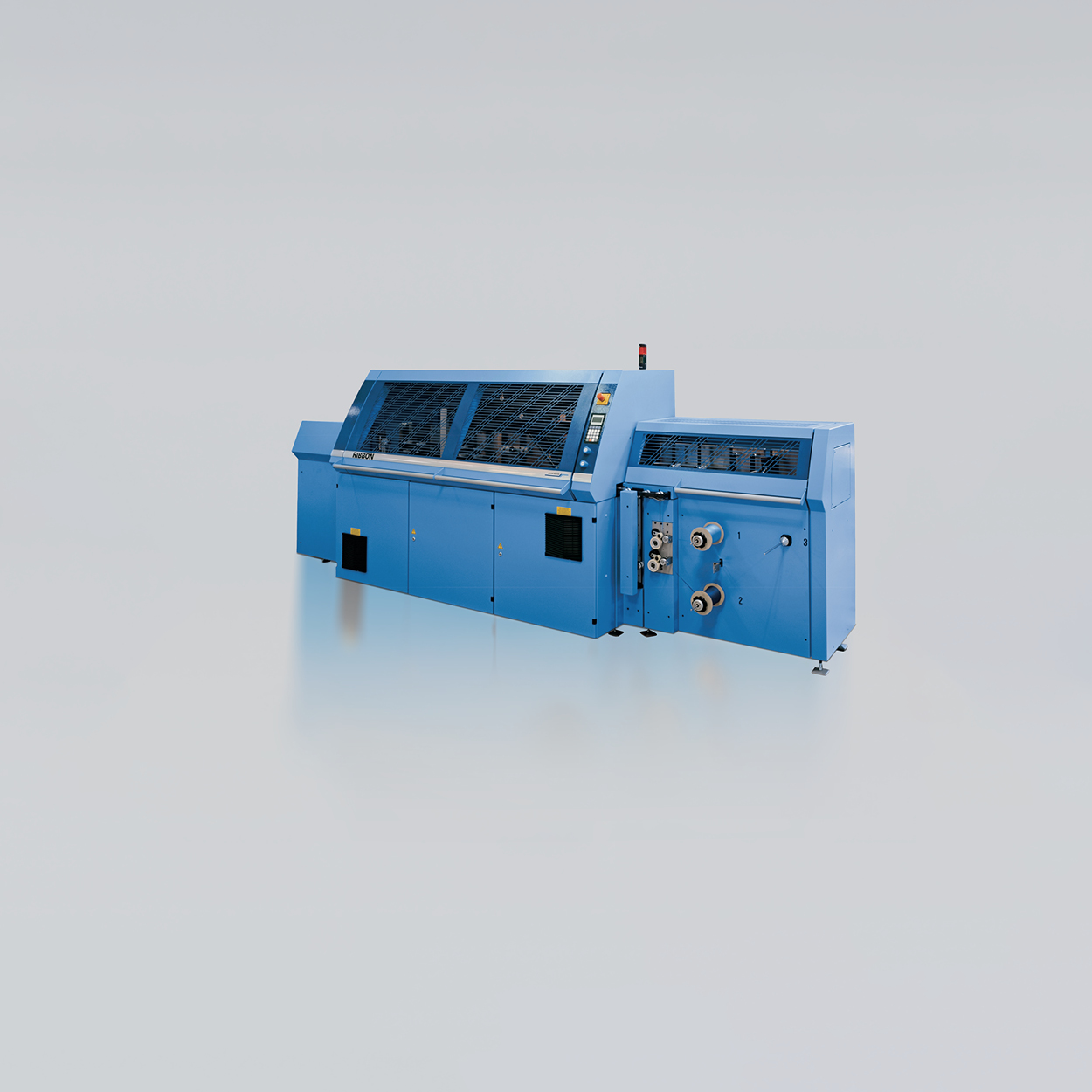

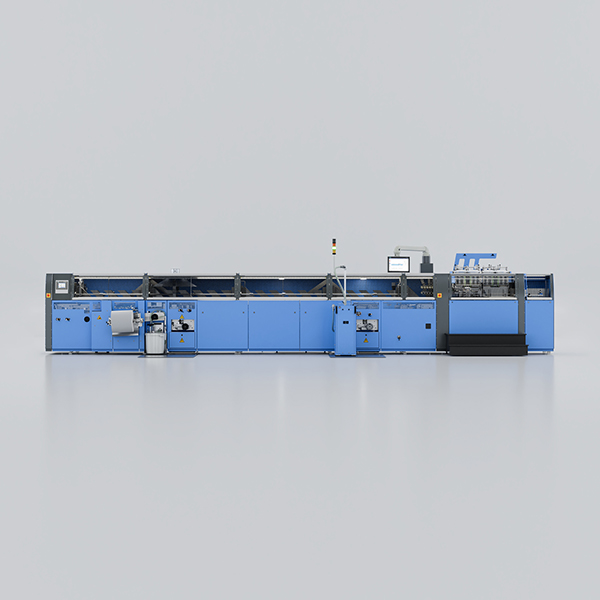

FM 700 | FN 720 | FN 700

Spine nipping for thread sewn book blocks

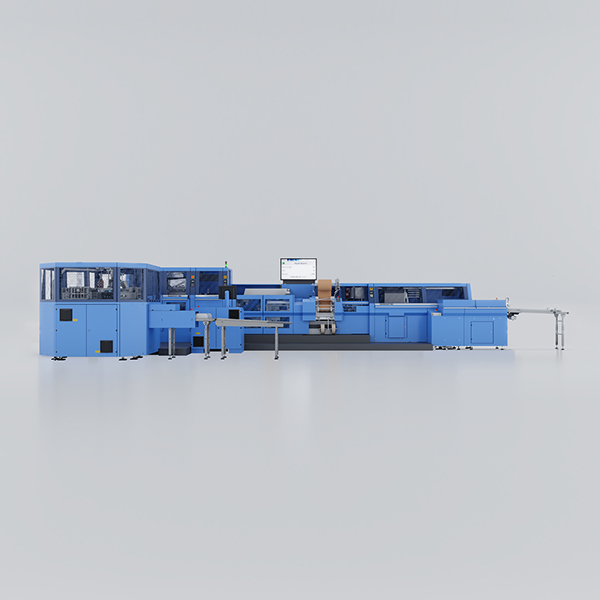

In hardcover production, the built-up of book blocks caused by folding and resulting from thread sewing is a well-known phenomenon. The built-up not only leads to problems in downstream processes, but also has a negative effect on the quality of the product – keywords glue penetration and uneven glue application. Muller Martini has the right answers to this challenge with the two FN 700 and FN 720 nipping presses and the FM 700 nipping and smashing press. The FN 700 (30 cycles/min.) and FM 700 (70 cycles/min.) can be used upstream of a backgluing machine. In addition, the FN 700 or the FN 720 (70 cycles/min.) are used between the dryer section and the three-knife trimmer after the backgluing machine. In the production of thread-sewn softcover books, the FM 700 also shows its strengths when coupled directly to the manual feeding station of an end sheet feeder upstream of a perfect binder.

Productivity

Can be used inline and offline with up to 70 cycles per minute.

High quality

With a pressing force of up to 150 kN the different nipping and smashing presses ensure particularly compact forming of the spine.

Functionality

Depending on the configuration, the presses can be placed upstream or downstream of a backgluing machine according to their function.

| Speed | 30 / 70 cycles/min |

| Format min. | 120 x 100 mm |

| Format max. | 510 x 320 mm |

| Thickness min. | 2 mm |

| Thickness max. | 80 mm |

| Pressing force max. | 60 / 150 kN |

Quick heads-up before you go

You’re about to open an external website (e.g. our virtual showroom or career portal). Please note that the privacy and cookie policies of that site apply, and we have no control over them.

If you’re okay with that, you can continue.