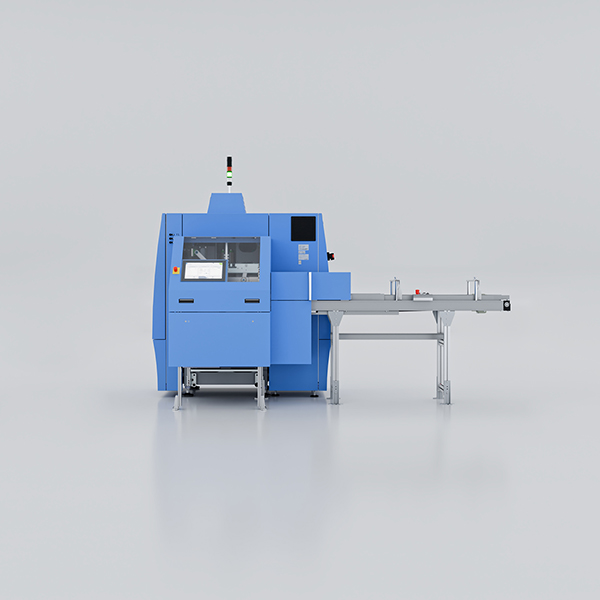

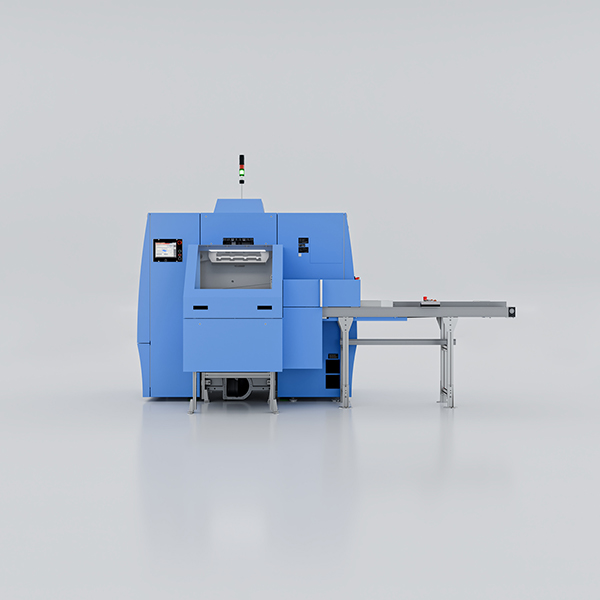

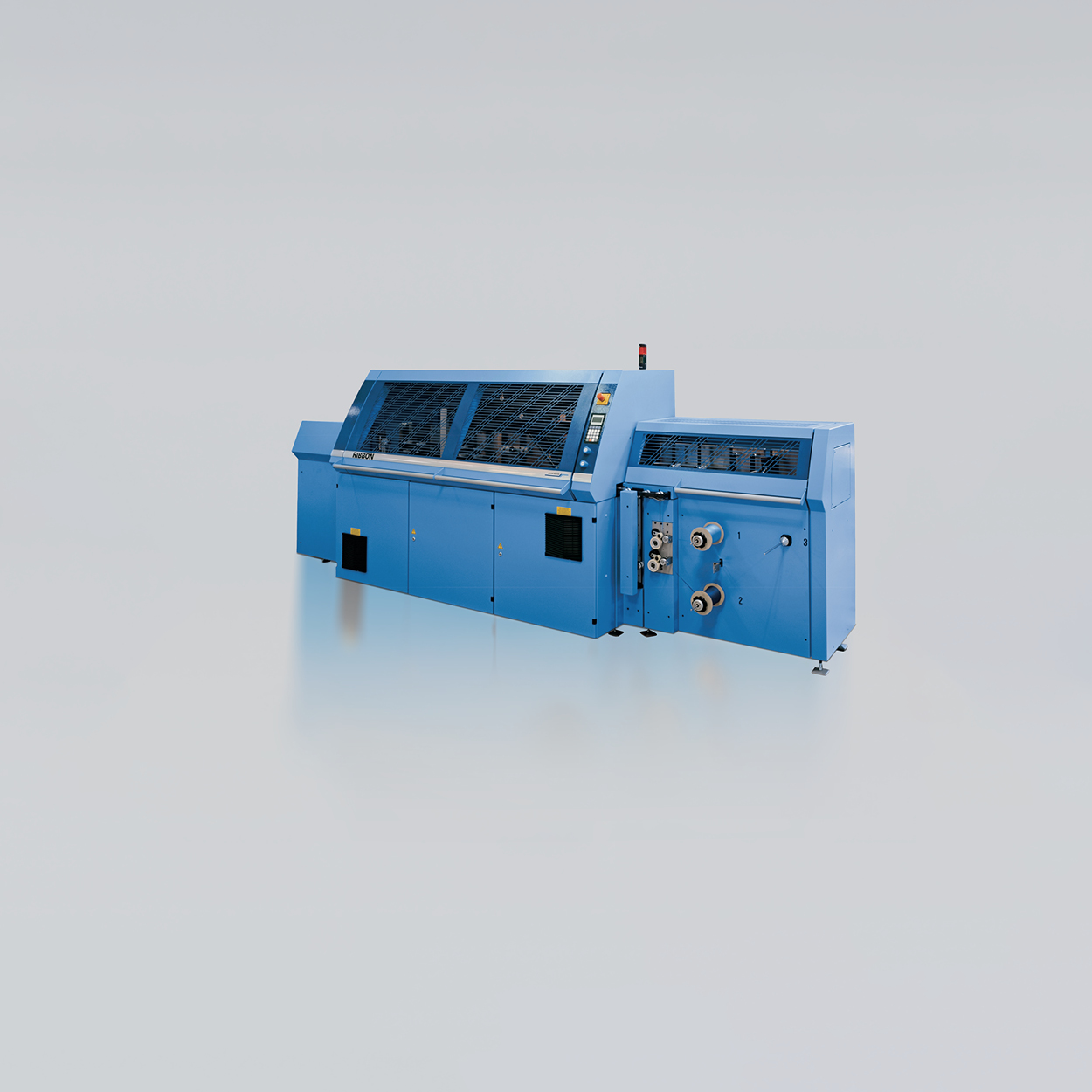

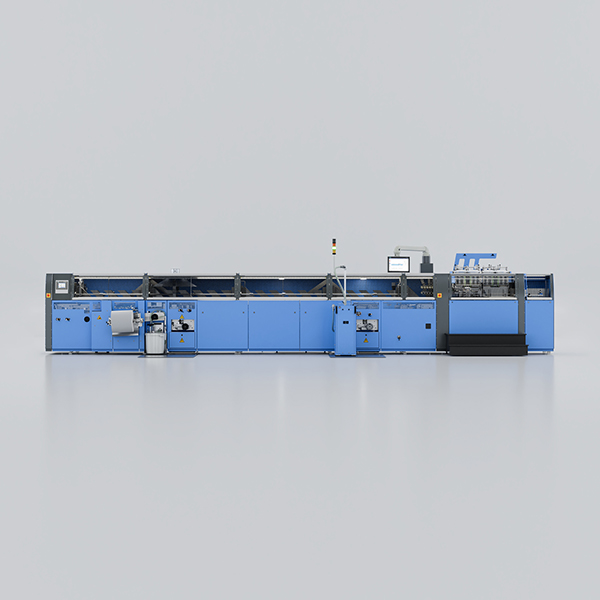

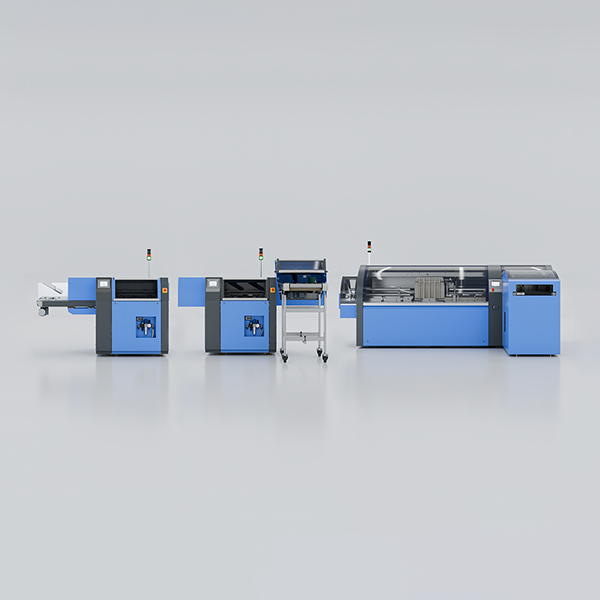

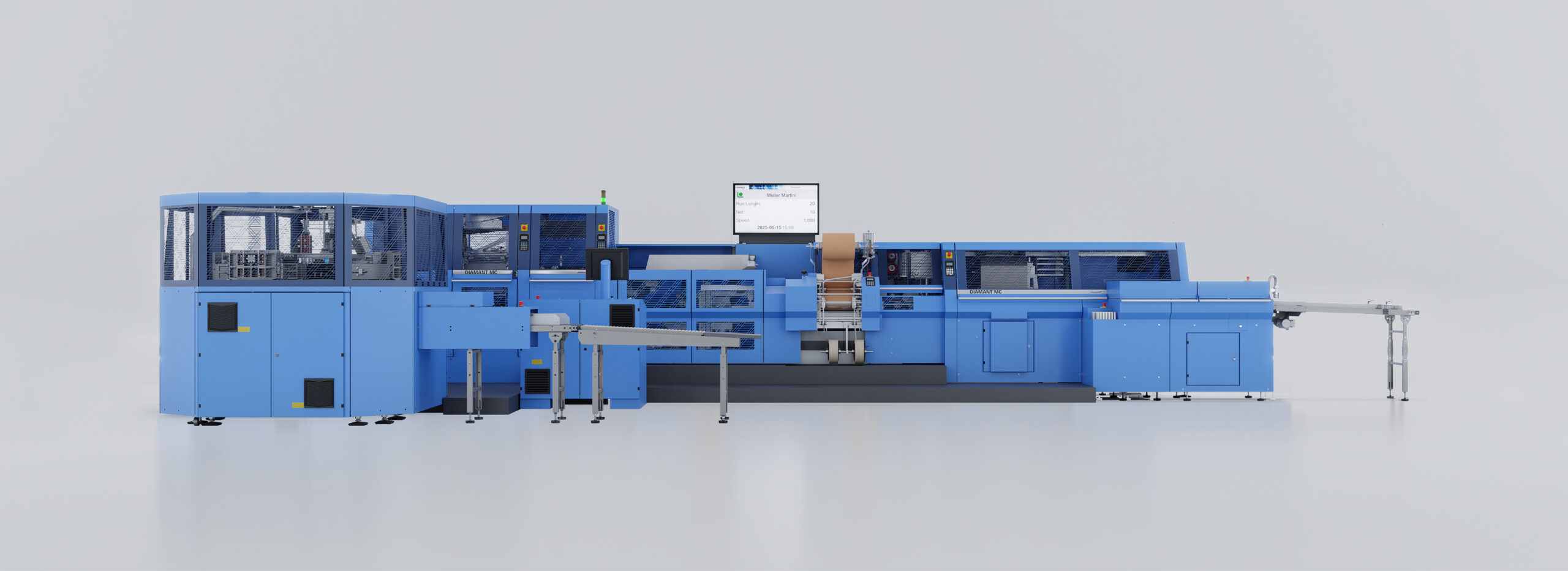

Diamant MC 30

Leap into Automation

The Diamant MC 30 book line is the ideal solution for companies looking to enter into industrial hardcover production. It combines high performance, flexibility, and an optimal setup – perfect for switching from manual processes to automated workflows. This configuration already features essential options, delivering excellent value for money.

Speed and automation

The Diamant MC 30 achieves a production speed of up to 30 cycles per minute. Fast setup times and a high degree of automation ensure maximum efficiency. Automated checks, such as headband supply, incorrect book block position, and double case checks, increase process reliability significantly while ensuring stable, dependable production.

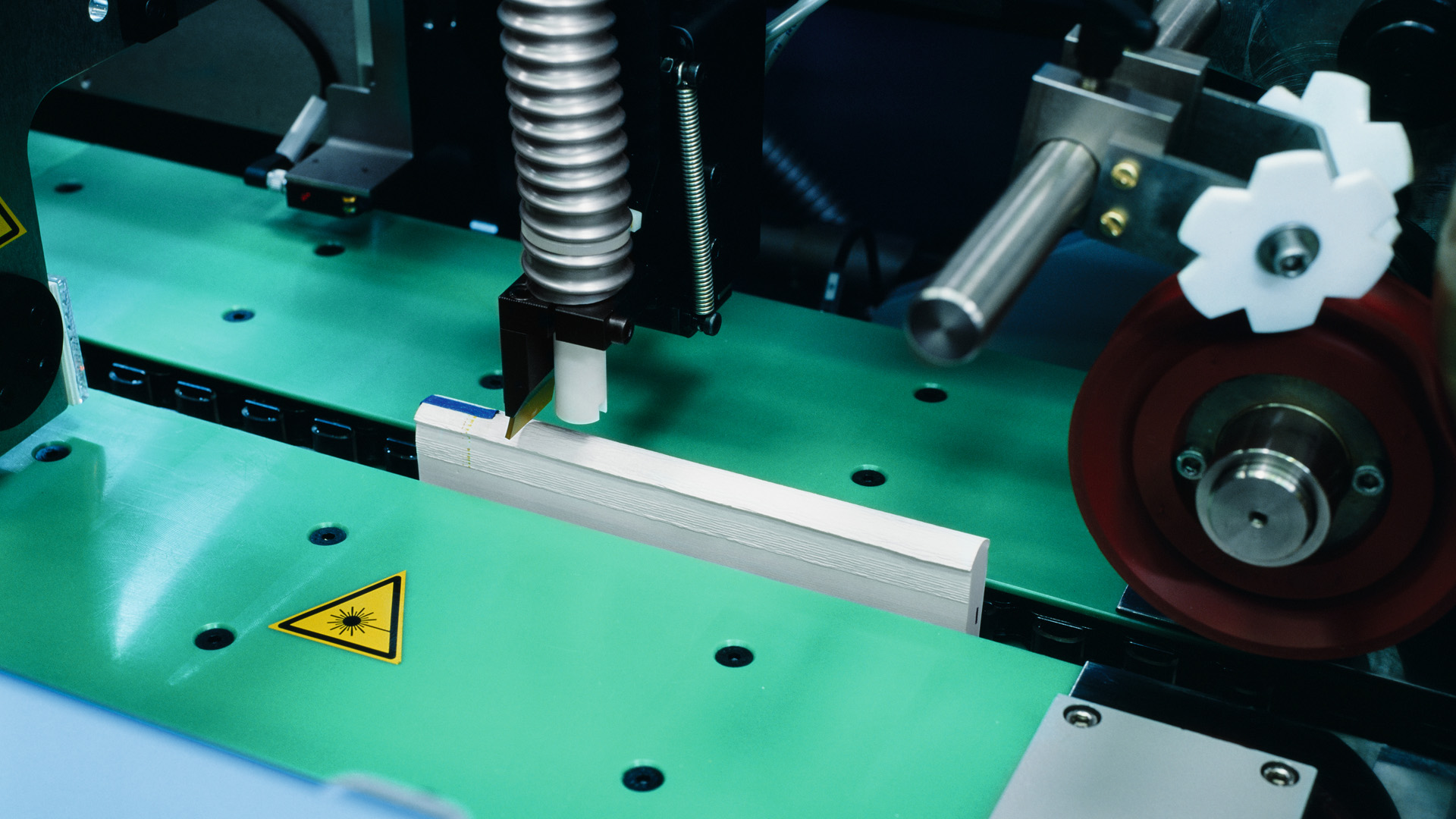

Precision thanks to Motion Control

The proven Motion Control Technology enables intelligent single drives at important stations, such as the rounding station, the transport chains, and the casing-in station. This ensures precise movements, which reduce downtime and boost output. The servo-driven rubdown device is perfectly synchronized with the paternoster knife, ensuring the book block is optimally hooked into the book case.

Proven features for maximum quality

The Diamant MC 30 covers a large size range and offers functions that can otherwise only be found in high-end book lines. The block spines are rounded evenly and under precise control, and double backing produces a permanent, fine fold. The integrated hotmelt fold gluing and a ribbon gluing device ensure high-quality processing and a perfect end product.

| Speed | 1’800 cycles/h |

| Format min. | 105 x 70 mm |

| Format max. | 390 x 305 mm |

| Thickness min. | 5 mm |

| Thickness max. | 90 mm |

Quick heads-up before you go

You’re about to open an external website (e.g. our virtual showroom or career portal). Please note that the privacy and cookie policies of that site apply, and we have no control over them.

If you’re okay with that, you can continue.