Corona Retrofit Paid Off

To ensure its operational safety and prepare it for at least ten more years of service, Appl in Bavaria, Germany, retrofitted the youngest of its three Corona C15 softcover lines. One by one, first the core binder, then the Orbit three-knife trimmer, and finally the gathering machine 3697 were equipped with new operator panels – plus a new main computer on the GM.

Perfect binders are the most complex systems for the production of print products. This makes perfect life cycle management crucial – and not just for the core binder, but also for the gathering machine, belt and drying paths, cooling towers, three-knife trimmers, milling cutters, and stackers. Retrofitting softcover systems that have been in operation for years in good time is an important step to ensure operational safety and extend the service life, not least due to the numerous electronic components.

When operator panels are discontinued

On older machines, for instance, both the control and the frequency inverter as well as the operator panel can be discontinued, meaning they are no longer available from the suppliers. In the event of a defect or failure, they can no longer be easily replaced – threatening production losses and long downtimes.

To prevent this, it is recommended to inspect the systems in good time. “After, we support customers in developing a future-oriented outlook for their production,” says Stefan Kocher, Product and Sales Manager Services at Müller Martini. “Tailored to the customer’s individual configuration and based on extensive life cycle management, our experts show what upgrades, retrofits, or spare parts can maintain or boost the productivity of a perfect binder.”

“Operational safety is essential”

No one knows this better than Alfred Mühlbauer. The industry expert with decades of experience is the head of finishing at Appl in Freising, Bavaria, where they exclusively produce perfect-bound products. These products are printed at the main location in Wemding, 120 kilometers away, where they produce inserts along with thread-sewn softcover and hardcover books.

“In our business, operational safety is essential when it comes to the journals and magazines we produce – which have to be delivered to subscribers and kiosks on time – but also for catalogs. That makes it important for us to be able to optimally plan our orders,” says the Appl signatory.

This is why, according to Alfred Mühlbauer, “looking towards the future, it made sense to retrofit our third Corona C15 line – especially considering I had heard about the discontinuation of the B&R control.” After an initial nudge from Frank Skorna, Regional Sales Manager at Müller Martini Germany, Appl invited Stefan Kocher and Stefan Schwartz, After-Sales Managers at Müller Martini Germany, to take inventory. The two of pointed out what they believed had to be updated, and executive management at Appl greenlighted the retrofit project immediately.

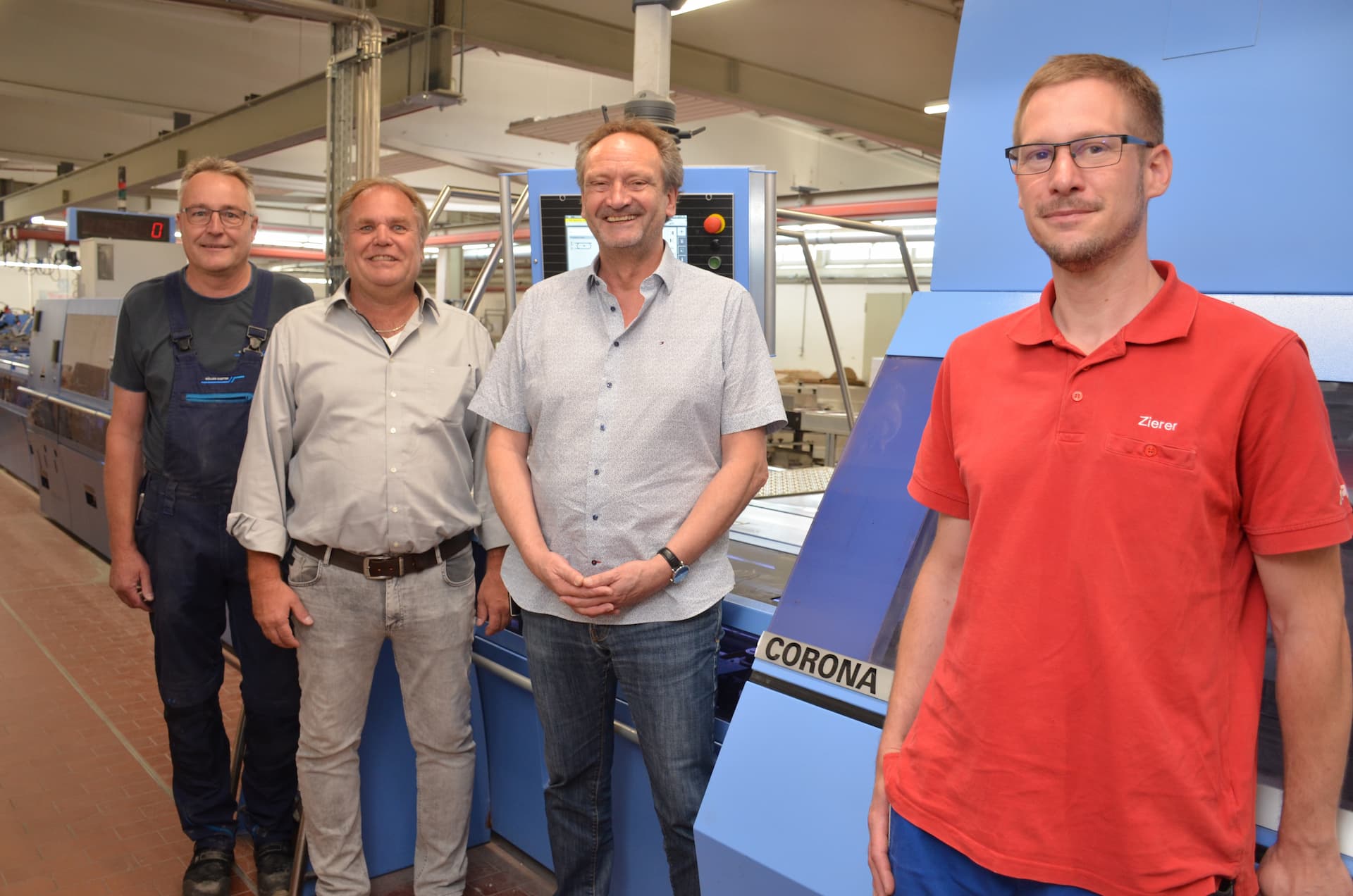

From right: Manuel Zierer (Deputy Department Head Appl Machine and Workshop Availability), Alfred Mühlbauer (Authorized Signatory/Head of Finishing at Appl), Stefan Schwartz (After-Sales Manager at Müller Martini Germany), and Peter Bauer (Technician at Müller Martini Germany) in front of the youngest Corona C15 at Appl.

“Everything went great – flawlessly”

The focus was on the third Corona C15, commissioned in 2018, purchased on the second-hand market, and still running reliably after all these years. “For us, it was clear from the start,” emphasizes Manual Zierer, as the Deputy Department Head Machine and Workshop Availability, “that we would be updating the entire line. Because if one component malfunctions, the entire system comes to a standstill.”

One by one, the operator panel was replaced, first on the core binder, then on the Orbit three-knife trimmer, and finally on the gathering machine 3697 – which also got a new main computer. These parts were all replaced as a precaution. All four of the elements replaced on the three machines were still working, but: you never know. Another benefit: The operator panels replaced on the youngest machines can be used as a backup or installed in older machines of the same type.

While Müller Martini had already replaced multiple Corona operator panels, the gathering machine and the Orbit at Appl were initial projects. In other words: Replacing the operator panel on the GM 3697 and the three-knife trimmer was a first for Müller Martini. And the customer was completely satisfied. “Everything went great – flawlessly, and within the intended timeframe of a week,” says Manuel Zierer.

At least ten more years

How many years has Appl extended the life of its third Corona C15 line by? Alfred Mühlbauer has a humorous and a serious answer in stock. First, the fun one: “I hope for at least three more years, because that’s when I retire…” And now the serious one: “I assume that the perfect binder will continue running for at least ten more years. Because first of all, Müller Martini is known for the high-quality design of its machines and their long service lives. And second, we have extensive in-house knowledge of our systems.”

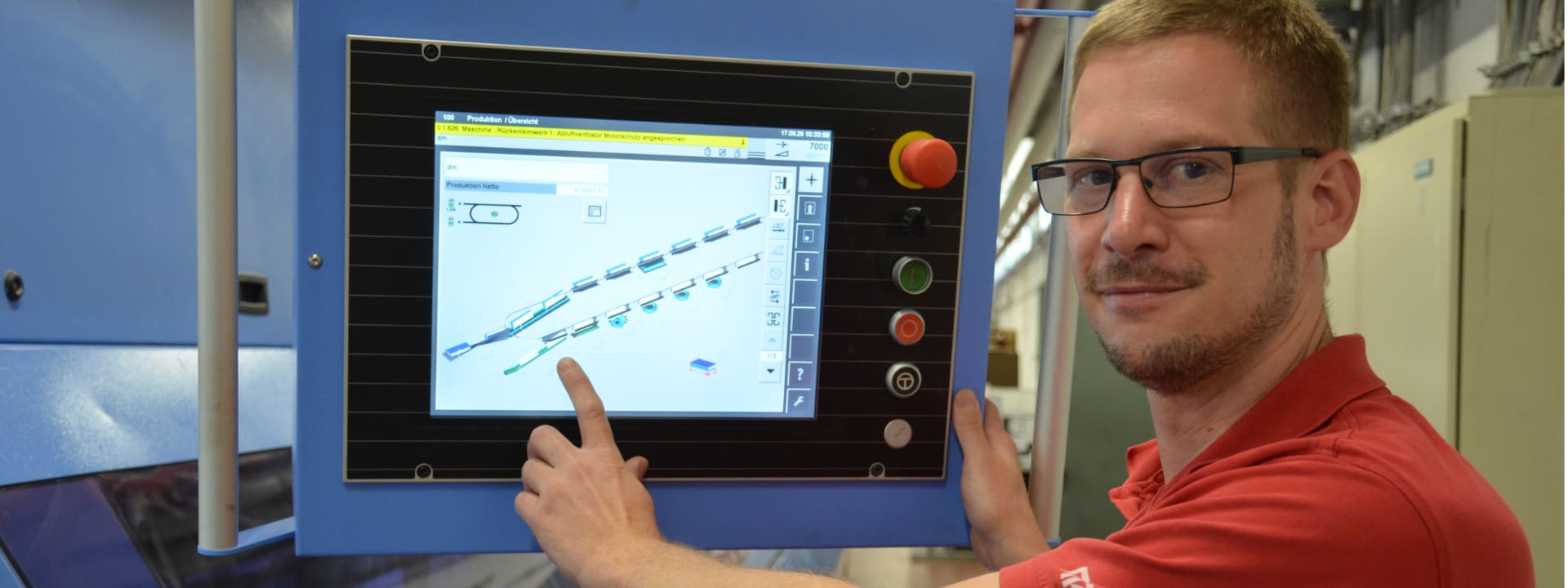

Next question: What effect do the new operator panels have on production? Manuel Zierer has two answers to this. “It was never our intention to boost performance with the retrofits – the focus was on operational safety. But: The work for our machine operators is now without a doubt easier and more convenient – not least thanks to the excellent instruction by Müller Martini technician Peter Bauer, who also performed the retrofits.”

Peter Bauer also replaced a Zenith operator panel, taking the opportunity to check out the three-knife trimmer of the second Corona C15 line at Appl.

Not just a retrofit – a full check of the entire line

While on the topic of Peter Bauer: He also replaced the operator panel of the Zenith three-knife trimmer on Appl’s second Corona C15 line from 2006 – also as an initial project and to the customer’s full satisfaction.

But he leaves no doubt, “that the retrofit of our youngest perfect binder was worth it – no question. And there’s another aspect to consider: During the retrofit, Peter Bauer performed a full check of the entire line. I’m glad that he spent an entire week on it…”

High flexibility thanks to different configurations

On their three Corona perfect binding lines, Appl produces journals, magazines, and catalogs, among other things – mainly for customers in Germany, England, and Switzerland.

Founded in 1899, the family business is now run by Markus Appl in the fourth generation. The company employs around 80 at its location in Freising, Bavaria. One special project at Appl is the telephone book. Despite digitalization today, it is still in demand: Last year, Appl produced around 60 million copies – in print runs between 20,000 and one million units per order.

Apropos print runs: Over the years, the three Corona C15 machines have produced well over one billion products. According to Manual Zierer, this makes Appl especially appealing to its customers, “because the three lines have different configurations. The two older lines have a pregluing and main gluing unit, which enables super clear glue application and greater durability of the print products. Line 2 also features a splitting saw and a Frontero front trimmer for the economic production of fold-out brochures in one pass. This gives us a high degree of flexibility.”

Print volumes have also continuously dropped at Appl in recent years, a trend that Alfred Mühlbauer says cannot be reversed. “But what hasn’t changed over time is customer demand for attractive products, high quality, and short windows. Our company is fully equipped to handle these requirements.”

Learn more about the extensive MMServices program on the Müller Martini website.