No Expiration Date on Our Packaging

Regularly investing in new machines – like the Solit PRO three-knife trimmer from Müller Martini this summer – is the recipe for success of bookbinder An der Reuss AG in Lucerne. For the innovative family business, other important cornerstones include a sustainable company philosophy – from low staff turnover to high consultation expertise, to exemplary energy efficiency, all the way to long-standing customer relationships.

Six years ago, An der Reuss committed to a groundbreaking investment. The traditional bookbindery, dating back to the year 1946 and under the ownership of the Dietrich family since 2002, replaced an ageing Acoro perfect binder from Müller Martini with its successor model Alegro.

Sample box quadrupled in size

“After commissioning in my opinion the best perfect binder in the world, we had significantly more selling points,” recalls Hansjörg Dietrich, emphasizing how quickly the new softcover system began delivering positive results. “We were then able to supply customers with Otabind as well as slip-fold and Swiss brochures.”

From right: Catherine Dietrich (Controlling & HR Administration), Hansjörg Dietrich (Head of Operations & Technology), Urs Dietrich (Head of Sales), and Georg Riva (Müller Martini) in front of the new Solit PRO three-knife trimmer at An der Reuss.

The sample box from An der Reuss is the perfect example for a major product expansion associated with the Alegro, designed to give the customers a taste of what the company has to offer. Until 2019, it included four copies – today that figure has risen to 16! “Because the machine covers it all, we can produce the entire softcover range,” emphasizes Urs Dietrich proudly.

A new Solit PRO three-knife trimmer

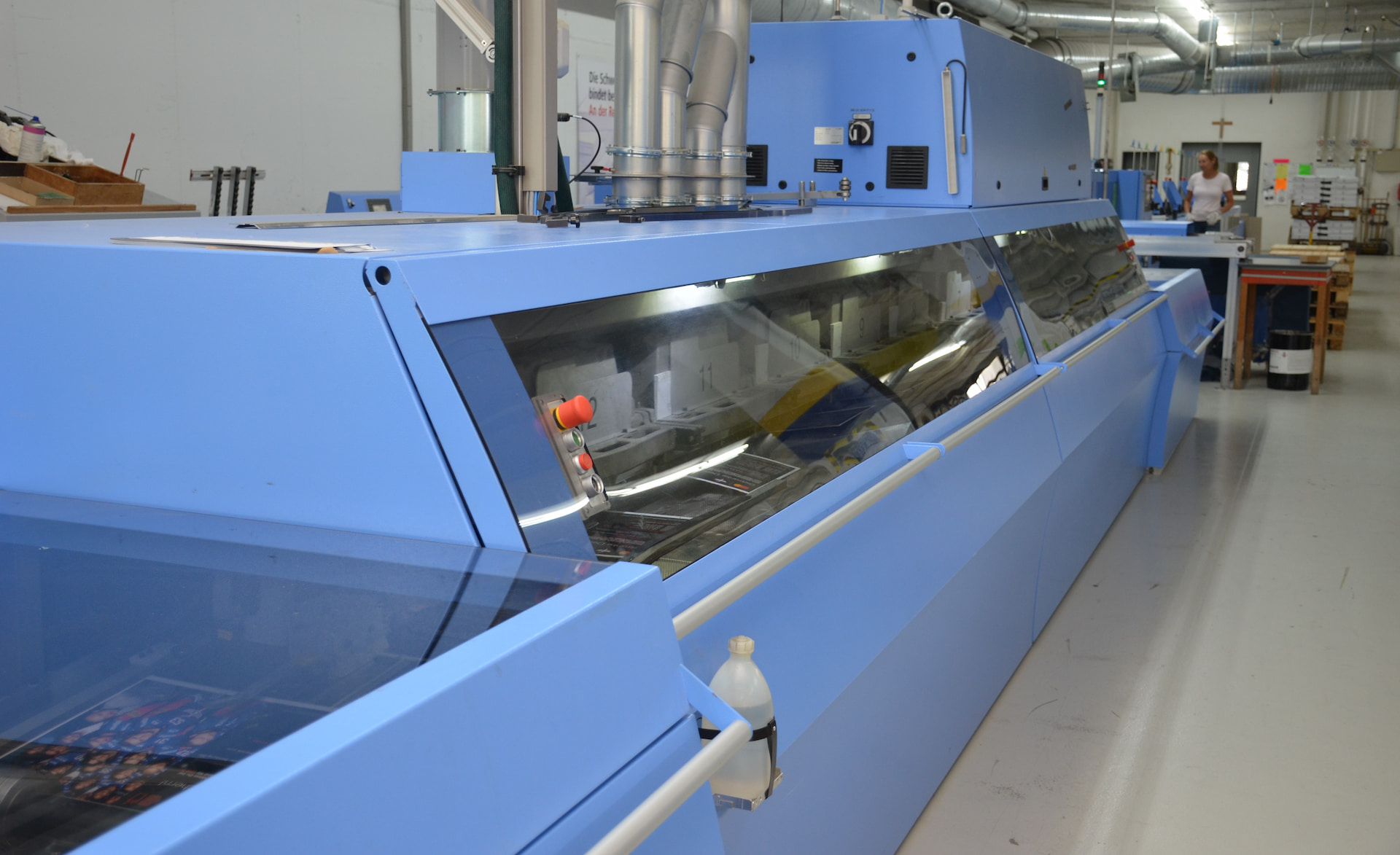

After using the Merit S three-knife trimmer from the Acoro downstream of the Alegro over the past six years, An der Reuss replaced it with a Solit PRO last summer. “Now, our entire perfect binder line finally has the same color,” says Hansjörg Dietrich, justifying the latest investment with a wink, adding a more serious argument: “We’re extending the service life of the entire line with this replacement. Thanks to Müller Martini’s modular approach, it’s really easy to modernize individual elements of a system.”

With a maximum rate of 4,500 cycles per hour, the Solit PRO offers various benefits.

- It scores with maximum production speeds in single-book trimming as well as the largest size range and the fastest setup times in its performance class.

- Launched and patented by Müller Martini initially for the upper performance segment, the SmartPress technology delivers first-class quality for both perfect-bound and thread-sewn products. Thanks to this unique, servo-controlled technology, air can escape efficiently from the book block. Finally, the pressing force is increased automatically for a perfect cut.

- It features a completely redesigned book infeed with telescopic belt, unwind roller, feeder hopper, transfer flaps on the cutting table, and servo-controlled, plunging infeed pusher. The exact synchronized infeed is taken care of by the gate rollers.

Besides faster setup times, Urs Dietrich emphasized three other advantages of the new three-knife trimmer: “Its blades have a much longer service life, it runs very smoothly, and thanks to optimal advance training at Müller Martini’s Print Finishing Center, which three of our employees attended, we were quickly able to use it in two-shift operation. Put simply: The Solit PRO has proven itself and we’re very happy with it!”

Investment in the next generation

According to Catherine Dietrich, regular investments in state-of-the-art technology are an important cornerstone of An der Reuss’ sustainable company philosophy. “On the one hand, we are signaling to the outside world that we believe in the future of our graphic design industry and will remain here for our customers for a long time to come. There’s no expiration date on our packaging!” At the same time, the family business also wants to send a signal to staff with its values and special spirit. “With new machines, we boost employee motivation and encourage tech-savvy young talent to enter our industry,” underscores Catherine Dietrich.

Each year, the innovative company organizes a trainee parkour, attended by more than a dozen in 2025, to win over young apprentices. One person who completed an apprenticeship as a print media processor with a concentration in binding technology (previously industrial book binder) at An der Reuss and was then offered a full-time position is Melanie Suhner. On the Müller Martini website, you will find her blog article “I think working with machines is cool” from March 2020.

Long-term planning reinforced

Speaking of staff: With 40 employees, An der Reuss is proud of both its low staff turnover and its high consultation expertise. According to Urs Dietrich, it’s quite high in demand when it comes to complex softcover products. “That’s why we set great store by reliability so that our customers always have the same contacts. On the other hand, this requires significant expertise to set ourselves apart from run-of-the-mill offers, especially considering the digital competition. We have several experts who have been working at our company for years, really understand the trade, and know how to create sophisticated print products efficiently and cost-effectively on an industrial scale.

Patrick Dietrich (left), holding a sample box, expanded from four to 16 copies following the Alegro installation, joined executive management of An der Reuss a few months ago. He is responsible for sales, together with Urs Dietrich.

This is one reason why An der Reuss expanded its executive management a few months back. In addition to Hansjörg Dietrich (Head of Operations & Technology), Urs Dietrich (Head of Sales), and Catherine Dietrich (Controlling & HR Administration), the board now also includes Patrick Dietrich (Sales) – nephew of Hansjörg and Urs –and Patrik Stotz (Head of Production). “This helps us diversify our strategic foundation while also reinforcing our long-term planning,” emphasizes Hansjörg Dietrich.

“Sometimes, it’s necessary to play hardball”

For An der Reuss, sustainability doesn’t just mean regular investments in machines and staff, but also high energy efficiency, a disposal concept (that is, recycling), and long-standing relationships with suppliers and customers. These are printshops from all over Switzerland. An der Reuss produces a wide range of magazines, brochures, and catalogs with variable sizes for them, with a clear focus on perfect binding. Saddle stitching (with a Primera E140 from Müller Martini) only represents a small proportion, while thread sewing (with a Ventura from Müller Martini) constitutes just under 10 percent. The print runs are rarely under 100 copies per title, sometimes going up to 200,000, but averaging between 2,000 and 3,000 copies.

“The industry is constantly evolving,” says Urs Dietrich. “Print volumes are declining, and products are no longer being made in some cases. The situation isn’t dramatic, but you have to adapt and sometimes play hardball.” But despite the shrinking market, Catherine, Hansjörg, and Urs Dietrich look to the future of their company with optimism: “We’re well positioned and have some great talent – in short: We rise to the challenges.”