From Print to Finished Book: Seamless Workflow Integration with Muller Martini and Hunkeler

In today’s fast-paced print industry, efficiency, automation, and flexibility are key points. Muller Martini and Hunkeler solutions demonstrate how tightly integrated systems can transform digital print finishing into a streamlined, error-resistant, and highly productive process.

With its versatile portfolio, Muller Martini and Hunkeler offer a wide range of solutions for various customers and applications – including end-to-end solutions that cover the entire process from the blank sheet or roll to the finished book. From digital presses Hunkeler Plowfolder/Starbook Sheetfolder series create precise book blocks.

The Vareo PRO and the Antaro Digital perfect binder from Muller Martini top notch variable on demand book production. The InfiniTrimtrim robot guarantees automated zero set-up trimming.

Depending on the setup, you can configure as needed the output ranging from 600 books up to 2,000 booksper hour – with minimal manual intervention.

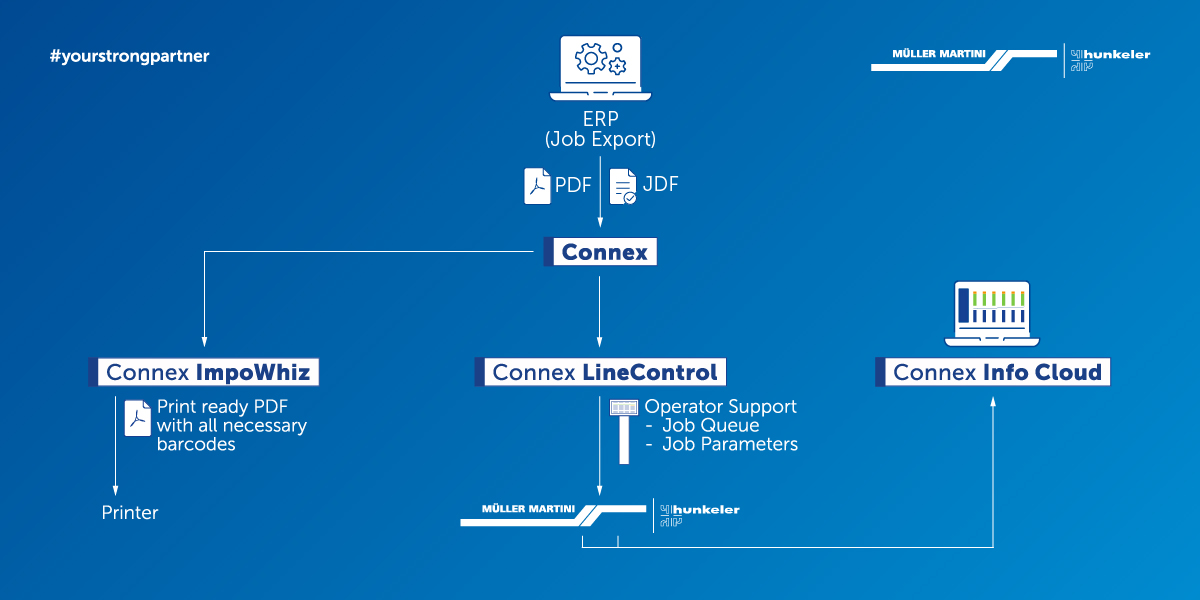

The Connex workflow system enables end-to-end, fully integrated smart factory solutions with machines from Muller Martini and Hunkeler. With its three modules, Connex ImpoWhiz (fast and automated imposition), Connex LineControl (job and queue management), and Connex Info Cloud (real-time monitoring and analysis), machines communicate seamlessly with each other and can be fully integrated into the customer’s system

Connex: The digital backbone

A seamless inline production line does not end with just the hardware. That’s why Muller Martini’s Connex is also used as a common workflow system for Hunkeler systems. With other words: the heart of this integration is Connex. It ensures:

- Fast and automated imposition via Connex ImpoWhiz – even for variable content and covers.

- Print image correction, preventing misalignment and maintaining visual consistency.

- Barcode-driven finishing, ensuring each book block is matched with the correct cover.

- Job and queue management through Connex LineControl, which communicates seamlessly with digital printing software.

- Real-time monitoring and analytics via Connex Info Cloud, accessible from any device.

Smart Factory in action

This collaboration exemplifies the Smart Factory concept: a fully automated, data-driven production environment where machines communicate seamlessly, errors are minimized, and setup times are drastically reduced. Whether producing short-run magazines, personalized brochures, high-volume softcover books or high quality hardcover books, the Connex workflow delivers unmatched flexibility and reliability with minimal operator intervention.

Experience the future of book production – get in touch to see Connex in action!

Yours,

Fabian Becker

Product Manager Connex and MPOWER, Müller Martini