With a new RF 700 backgluing and backlining machine, D.R.J. Tiskárna Resl s.r.o. in Náchod in the Czech Republic not only relieves the Alegro perfect binder, which was previously also used as a gluing machine, but also significantly increased profitability.

Diamant MC 35 bookline,

Ventura MC 200 thread sewing machine,

Alegro perfect binder, Presto II saddle stitcher, Jack Plus dust jacket machine – the production hall of this full-service graphic arts company, which offers its predominantly Czech customers all forms of finishing, looks like a Muller Martini showroom (see picture above). Six months ago, Tiskárna Resl, which has three RMGT presses with twice four and once eight printing units, put another Muller Martini machine into operation in an adjacent room – an RF 700 backgluing and backlining machine with an attachment feeding station and a second

Granit three-knife trimmer (the first is located behind the Alegro line).

Several advantages

Not only did it replace an offline VBA face sheet feeder, which is now for sale and was built at the time by Muller Martini as a special design for Tiskárna Resl, but it also relieves the Alegro, which served as a backgluing machine for hardcover products. The fact that the perfect binder can now be used exclusively for the production of softcover books is the one major advantage, according to Jiří Resl junior – together with his brother Tomáš, managing director of the family business founded in 1991 by their father Jiří Resl senior. The second: thanks to higher automation, the company, which employs 30 people, saves time and personnel.

"We have doubled productivity compared to the previous VBA offline solution." In addition, there are three other advantages, according to the company CEO. "First, we can now plan much better thanks to the shorter deadline windows. Second, the quality of the books has improved markedly thanks to two press units upstream of the attachment feeder and downstream of the gazing station. And thirdly, the similar operating philosophy of the other Muller Martini systems allows us to exchange machine operators."

According to Jiří Resl, it also proves to be a plus "that Muller Martini is the only manufacturer of graphic machines to have its own agency in the Czech Republic, which of course gives us many advantages in terms of service and language."

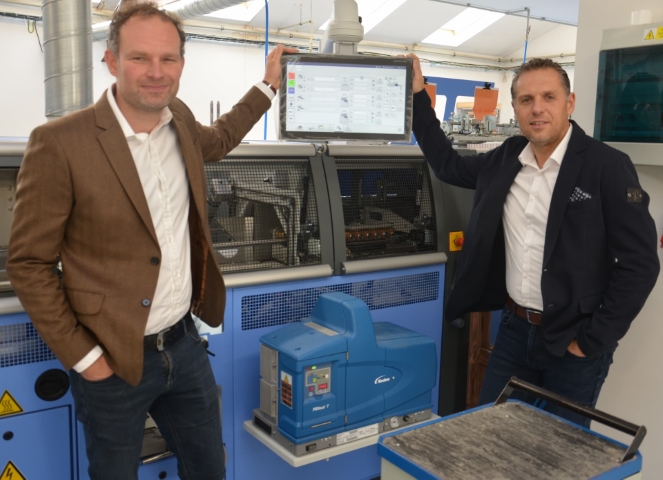

Jiří Resl junior (right), Managing Director D.R.J. Tiskárna Resl: "Thanks to the shorter deadline windows, we can now plan much better." Left Lubos Kunze, Managing Director Muller Martini Czech Republic.

More hardcover orders...

Jiří Resl junior (right), Managing Director D.R.J. Tiskárna Resl: "Thanks to the shorter deadline windows, we can now plan much better." Left Lubos Kunze, Managing Director Muller Martini Czech Republic.

More hardcover orders...

Due to travel restrictions, Jiří Resl had not seen the RF 700 live before deciding to buy it, but in an online demo. "Unfortunately, it was not possible otherwise at that time. But frankly, I prefer a personal impression of new machines when making major investments."

The hardcover spectrum produced by Tiskárna Resl – just as in saddle stitching and perfect binding – is extremely diverse. It ranges from fiction and memoirs to tourism, cooking, technology and smaller quantities of school books. After investing in the RF 700, the company, which also has a freight forwarding company with several trucks and a travel agency attached, has noticed a significant increase in hardcover orders. According to Jiří Resl, this is due in no small part to the fact that "demand for hardcover books has increased in the Czech Republic – people are happily reading more again."

...but large fluctuations in orders

To what extent this is due to the corona crisis, the company boss is not able to judge. "What is certain, however, is that the pandemic is also having an impact on our production. There is a certain nervousness, and we are experiencing large fluctuations in orders. However, we can absorb these well thanks to the great flexibility of our staff."

In addition, as Jiří Resl points out, there is the current worrying situation regarding raw materials such as paper, printing plates and inks. "We are suffering not only from long delivery times, but also from increased prices. But for me there is no doubt: those who survive this will come out of the crisis stronger. And Tiskárna Resl will definitely be one of those companies, because we are very innovative."

RF 700 – the most universal gluing solution for thread-sewn book blocks

The RF 700 backgluing and backlining machine, which is used for gluing and rebating thread-sewn book blocks, can be configured as a 30- or 70-cycle/minute line. A 30-cycle machine can – under certain conditions – be expanded to 70 cycles if market requirements change, thanks to Muller Martini's modular system. This means that bookbinders not only have the fastest gluing machine on the market, but they also have a high level of investment protection.

The RF 700 can be used in book production lines with upstream and downstream presses (up to 60 kN press force) for perfect book block shape and quality (avoiding spine pitch), but can also be designed as an offline solution. In addition to its compact design and high running speed, the RF 700 offers great flexibility in the selection of glues and combinations for gluing. The CoPilot system enables efficient operation and the fastest possible makeready times.

In short, the RF 700 guarantees perfect preparation of thread-sewn book blocks for industrial hardcover production.