Westermann Druck: Celebrating 175 Years A New Publica PRO Perfect Binder

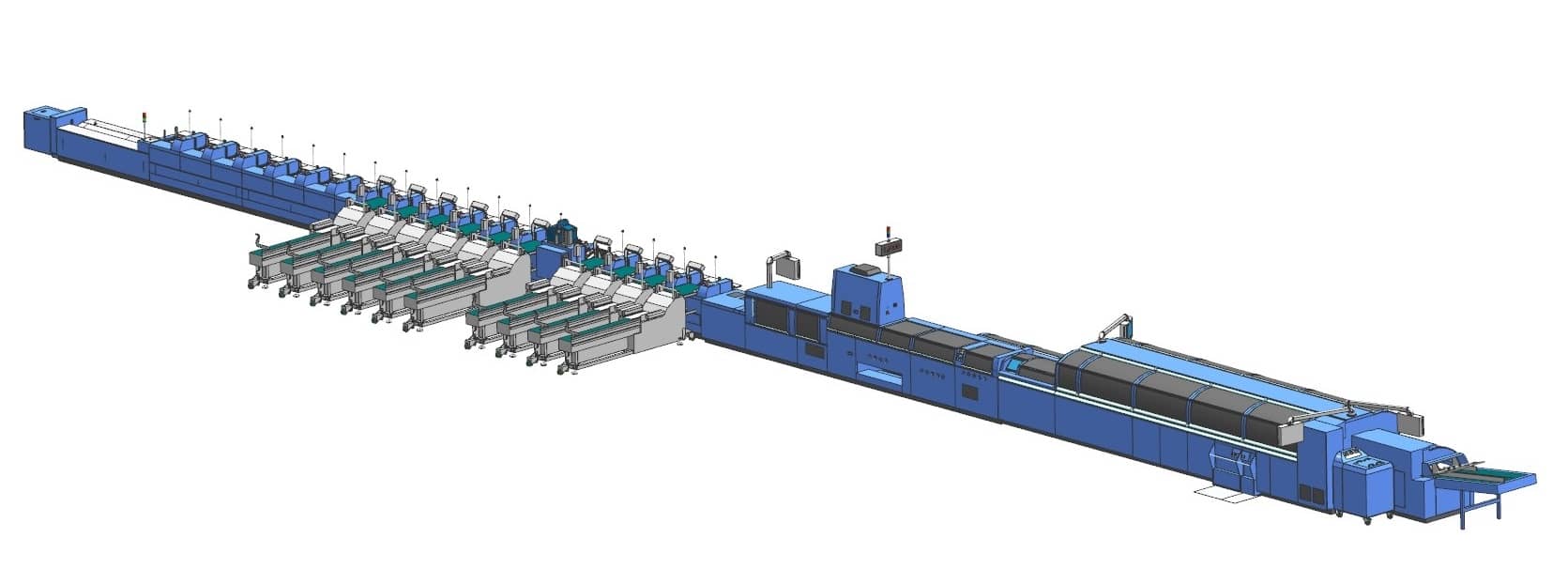

Just in time for the company’s 175th anniversary, Westermann Druck GmbH is investing in a new high-performance Publica PRO15 perfect binder from Muller Martini for its plant in the German city of Braunschweig.

Starting this summer, Westermann Druck GmbH, which had operated three plants employing a total of 900 people, will concentrate its operations at two of its production locations – in Braunschweig and Zwickau. The company, which produces around 33 million softcover products annually, with a focus on magazines, catalogs and (text)books, had originally planned to move a Muller Martini Corona perfect binder from the company’s closed plant in Landau to Braunschweig (where 230 people will be employed) and continue to produce there using two lines.

The new high-performance Publica PRO impresses with several technological innovations.

The new high-performance Publica PRO impresses with several technological innovations.

However, by providing a detailed business plan, Muller Martini showed Westermann Druck that a new investment in the latest technology would be substantially more cost-effective than operating two older machines. The "two into one" concept convinced the company to opt for the new high-performance Publica PRO15 from Muller Martini, which is capable of producing at 15,000 cycles per hour. An 18-station ZU 842.C gathering machine was added and Westermann Druck GmbH relies on existing (Muller Martini) peripheral systems.

The Publica PRO, which is available in three performance segments (12,000, 15,000 and 18,000 cycles per hour) is one of the newest machines that Muller Martini had intended to present at drupa 2020, which has now been postponed. It has several impressive technological innovations, including

- a new monitoring connection (no more plus/minus buttons in the belt area),

- a new copilot system (19-inch multi-touchscreen with the same swipe function as smartphones),

- an optimized clamp chain (which minimizes wear and tear because the clamp chain is smaller and by adjusting the chain drive),

- new side gluing disks (reducing the “ELSe” problem through a slanted arrangement)

- and optimized cover transport (improved scoring quality and precision through the use of ball screws).

The final contract negotiations between long-time partners Westermann Druck and Muller Martini took place via Skype because of the coronavirus pandemic. The new perfect binder will commence operations in September. In addition to the Primera saddle stitcher from the Landau plant, the Westermann Druck facility in Braunschweig will be using three other Muller Martini systems: two other saddle stitchers (an SH 300 and a Bravo) and a VenturaConnect integrated book sewing system. There will also be a Kolbus-brand BF 526 hardcover bookline.