D.R.J. Resl Expands into New Market Segments with the Diamant MC 35

06/09/2016

The finishing set-up of D.R.J. Resl in the Czech town of Nachod was only lacking hardcover to be complete. The gap will be closed this fall, however, with the commissioning of a Diamant MC 35 bookline.

D.R.J. Resl, which employs 40 people and specializes in magazine and books (including school textbooks) in the run segment of 2,000 to 5,000 copies, relies on Muller Martini’s state-of-the-art solutions to meet its print finishing needs – the company currently uses a Presto II saddle stitcher, a Ventura MC 200 thread sewing machine, and an extensive Alegro perfect binding line with a 3692 gathering machine, a mull feeder, a VPN/PUR nozzle, a Granit and – as a recent addition – an endsheet feeder. “I consider Muller Martini to be the clear leader when it comes to print finishing,” says Jiri Resl at drupa in Düsseldorf.

The company owner therefore had no doubts about which supplier to turn to when it came to investing in a new bookline. In September, the three existing Muller Martini systems in Nachod will be joined by a Diamant MC 35. “We aim to extend our product range, produce books with added value and tap into new market segments,” says Jiri Resl. In addition to school textbooks, Jiri Resl has got his eye on technical literature in particular.

The family business has accepted hardcover orders from its customers even before now, but currently still has hardcover books produced by external partners. Jiri Resl is convinced that the commissioning of the new Diamant MC 35 will deliver “an improved production workflow, shorter turnaround times and higher book quality.”

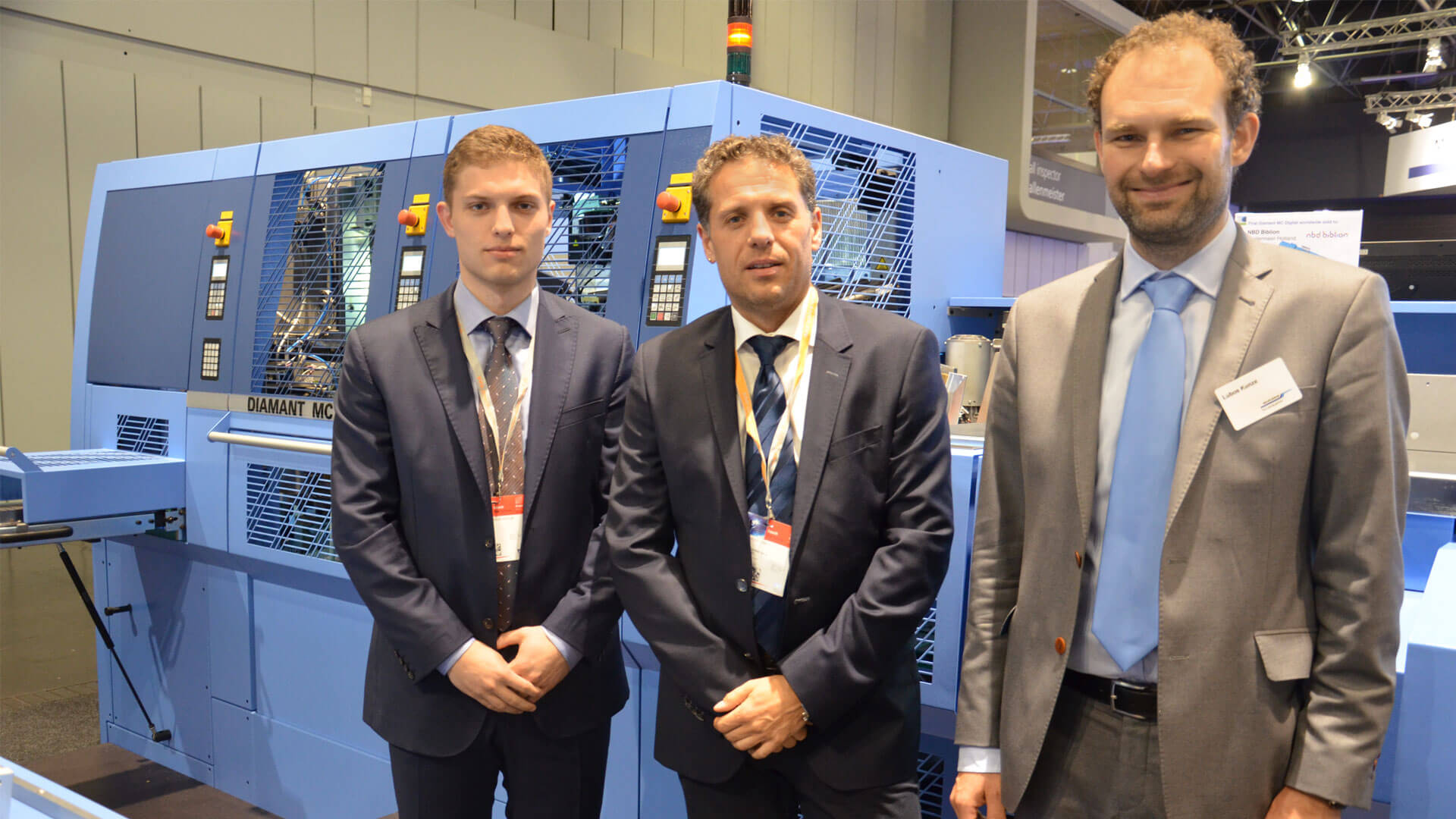

Jiri Resl (center) and his son Vojtech (left) together with Lubos Kunze (Managing Director of Muller Martini Czech Republic) in front of the Diamant MC 35 at the drupa booth in Düsseldorf.