Touchless workflow is an integral building block of Muller Martini’s Finishing 4.0 engineering philosophy. It provides the intelligence and automation to help speed the processing of products that are printed traditionally, digitally, or in combination to handle changeovers largely without operator intervention.

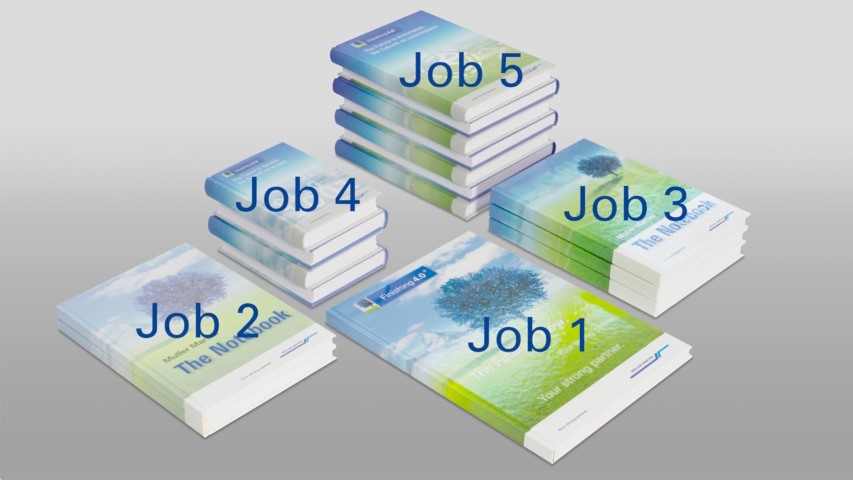

Recently, I visited our factory in Germany to conduct a series of touchless workflow trials on hardcover finishing. The production consisted of running books in very small batches with varying formats. The books were flat-backed without headbands. Utilizing Muller Martini’s Diamant MC Digital, the trial then simulated a Touchless Workflow based on client-specific data (e.g. format, print run, job parameters, etc.) which had been pre-loaded into our factory’s workflow server.

The Diamant’s existing servo technology and automation platform, in combination with the Touchless Workflow enabled the line to changeover automatically driven by barcode in what’s called a “segmented changeover.” As soon as books cleared the first portion of the line, that section began to automatically setup for the next job. This allowed the operator to keep flowing through changeovers without stopping production.

We witnessed extremely efficient Touchless Workflow hardcover production that can significantly automate an operation and improve throughput.

Depending on your specific capabilities and job parameters, there are several ways to achieve a Touchless Workflow in hardcover production, including:

- Template-based Workflow: If you process a limited number of formats (for example, photobooks that have standard trim sizes), you can utilize a simple barcode scan on the first case to embed the proper template. It’s a relatively simple Touchless Workflow solution, independent of an external data connection.

- Server-based Workflow: At the factory trial, Muller Martini created multiple job-files in the factory´s workflow server that included the relevant data. We then downloading that information from the workflow server by scanning the corresponding barcode. In the real world, an FTP connection to the customer’s MIS system would download from the server all of the relevant format data. In a production environment, this process would travel outside our system and go to the client’s system to pull and load information for job setup. That may sound a little arduous, but it’s actually done very, very quickly and easily by the system.

An important benefit of a server-based workflow is that information can be garnered and analyzed after the job is run. Because job parameters are embedded within the customer’s MIS, critical data can be captured and fed back to reveal highly specific outcomes; for instance, Batch #6 only ran 11 books instead of 12. What’s more, you can determine at what point on the line a bottleneck occurred—and rectify the issue during production.

- Connex Workflow System: Muller Martini’s ConnexLine Control helps manage and supplement the information flow between the production environment and customer´s MIS . Furthermore, ConnexInfo 4.0 provides highly granular information about the performance of the line, capturing such data as stops, delays, and run times, error messages and shows an overall efficiency.

Ultimately, what this particular trial showed is that Touchless Workflow clearly improves the efficiency of ultra-short hardcover on demand digital production. In addition, it can be achieved by having job data either downloaded from the customer’s server or preloaded by a template.

How are you handling your job changeovers in this ever changing world of shorter and shorter runs?

Touchless Workflow on the bookline

Our video shows, how very small batches are produced on the Diamant MC Digital.

Watch the video on YouTube