Did you know that, over an average of ten years' service, your conveyor's chain covers a distance equivalent to several orbits around the world (exactly 4.5 times)? Despite this top level of use, I very often experience that the least attention is given to the newspaper conveyor. Probably because its function does seems relatively banal. But only until it fails, for whatever reason, thereby paralyzing the entire newspaper production.

Since customers have often omitted several investment cycles in recent years, we see outdated installed bases in many mailrooms – including, of course, among newspaper conveyors. This is exactly where our life cycle management comes in. We help you prevent impending production downtimes and make your transporters fit for purpose again.

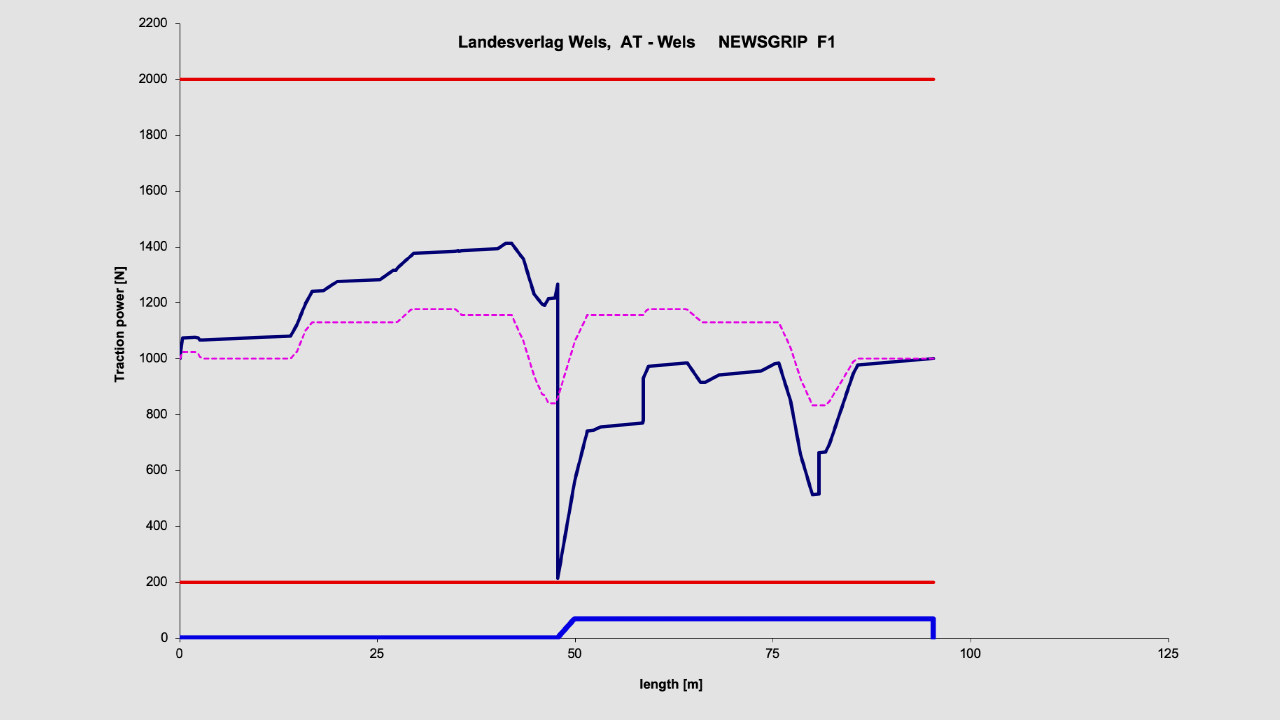

With newspaper conveyors, everything starts with a thorough inspection, both visually and using a chain control unit. This practical unit detects whether the track rollers are in place or worn and also measures how strongly the chain is stretched and how reliably it can still be used. Our qualified plant engineers also carry out very comprehensive checks on the transfer station, the checking copy/waste copy extractor, the auxiliary drive, the newspaper delivery to FlexiRoll buffer, and the compensating stackers and rail profiles. They identify all the wear parts and draw up a detailed inspection report which is used to prepare a customer-specific retrofit repair offer.

Incidentally, such inspections naturally make sense for all machines in the mailroom. At the same time, a medium-term strategy is also important for you to keep your plant running reliably. In a personal consultation, we will discuss updates, upgrades, retrofits or a spare parts strategy with you. Remember that more and more electronic components are being phased out, which inevitably leads to a retrofit of a NewsGrip conveyor control.

It's important for you to know that the approach to consultations for our mailroom customers is highly individual and specific so that the implemented measures make sense for each individual mailroom with all its unique conditions. To avoid major cost items, the measures are prioritized, always with the aim of continuing to ensure your production.

Chain measurements are an effective tool to prevent damage.

For long-term security, a maintenance contract can be concluded in addition to preventive inspections. Since there is a tendency toward using fewer and fewer machines for the same run in the mailroom, higher utilization levels are being seen for the individual machines and components. Nevertheless, in order to extend the economic life-time of your equipment, we have individual maintenance contracts adapted to customers and their order structure. A popular variant is our FlexoTage. You book any number of service days per year and can then use these for repairs or inspections as required.

And another tip about conveyors: During recent inspections, our engineers discovered conveyors with chain and rail profiles that had seen above-average wear and had lost a great deal of efficiency in production. That's why I highly recommend that you take a close look at your conveyors to check whether there is any risk of a costly failure.

Newspaper conveyors are the backbone of every mailroom. Therefore, plan an inspection to ensure that they continue to function reliably.

Best wishes,

Stefan Kocher

Product and Sales Manager Service Program