That's the slogan of Hunkeler Innovationdays 2023 – and it can only be achieved with end-to-end, networked production workflows. Only in the context of networking does data-driven process optimization or "machine learning" become possible. What was presented as a concept just a few years ago is slowly but surely taking on concrete form. On the one hand, the result is an enormous increase in efficiency throughout the entire production process. On the other hand, new application possibilities and new business models are opening up.

Anyone who wants to get an overview of high-speed digital printing in its various forms today will not be able to avoid a visit to the Hunkeler Innovationdays. That is why the popularity of the industry event is so great this year, both from the exhibitor and the visitor side. More than 100 exhibitors are showing their systems and solutions in Lucerne, and over 6,000 visitors from all over the world are accepting the invitation. Among them, as the organizer emphasizes, are almost exclusively decision-makers.

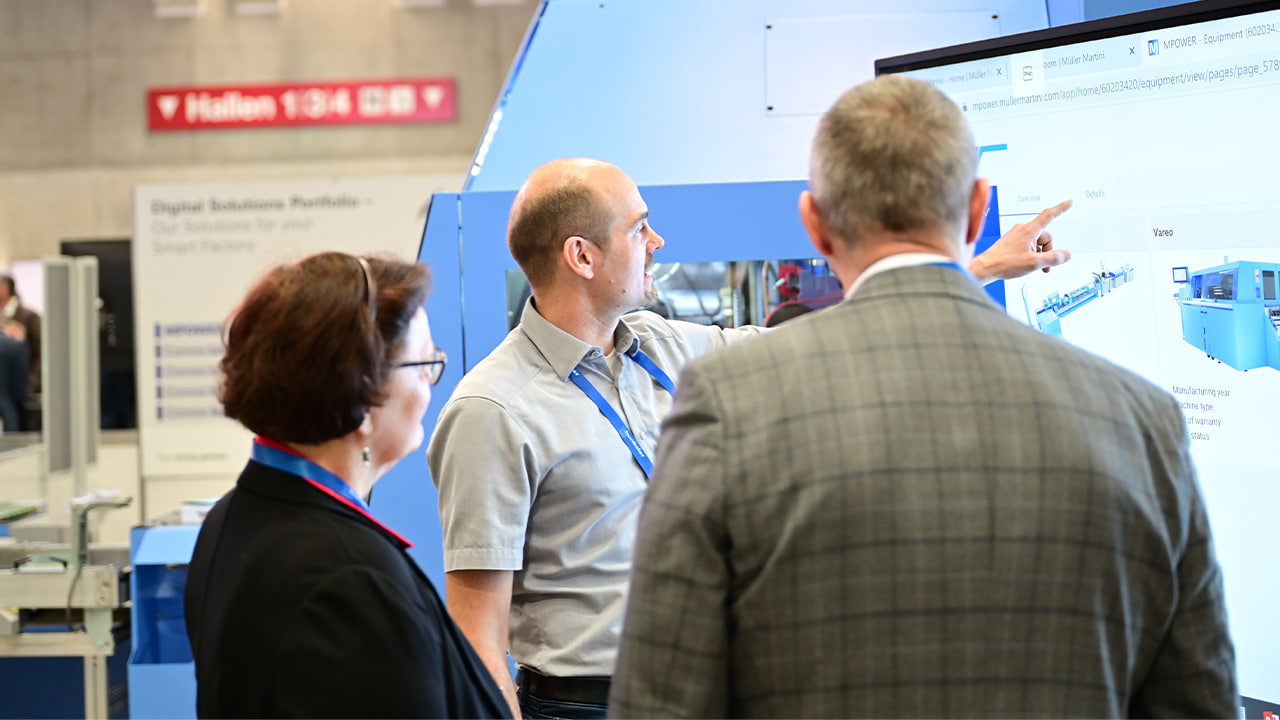

In addition, it is the first major international live event of the graphic arts industry after the pandemic. As they walk through the exhibition halls, it is noticeable that the visitors have missed the face-to-face exchange in recent years. After all, human communication cannot be shifted completely to digital platforms.

Hotspot of digitization

The challenges currently facing the printing industry are largely the same in all markets. The shift in advertising and communications budgets continues, with no end in sight. Rising energy costs have fueled inflation significantly, the supply chain problems are not yet completely off the table either, and all industries are affected by the shortage of skilled workers anyway. Against this background, the pressure for further automation in the printing industry continues to increase.

At Muller Martini, the

Prinova Digital saddle stitcher line celebrated its premiere, taking automation to the extreme. The saddle stitcher line starts with an unwinding station including a sheeter and a folding machine, after which the Prinova Digital takes over the gathering and stitching of the various print products.

In live demos, four jobs are produced in a first sequence in different run lengths between five and 35 copies and with different page counts. The format changeover for the next job sequence takes just 58 seconds, after which three more jobs are produced in different runs. This also creates a hybrid product where offset-printed signatures and a cover are added in addition to the digital content.

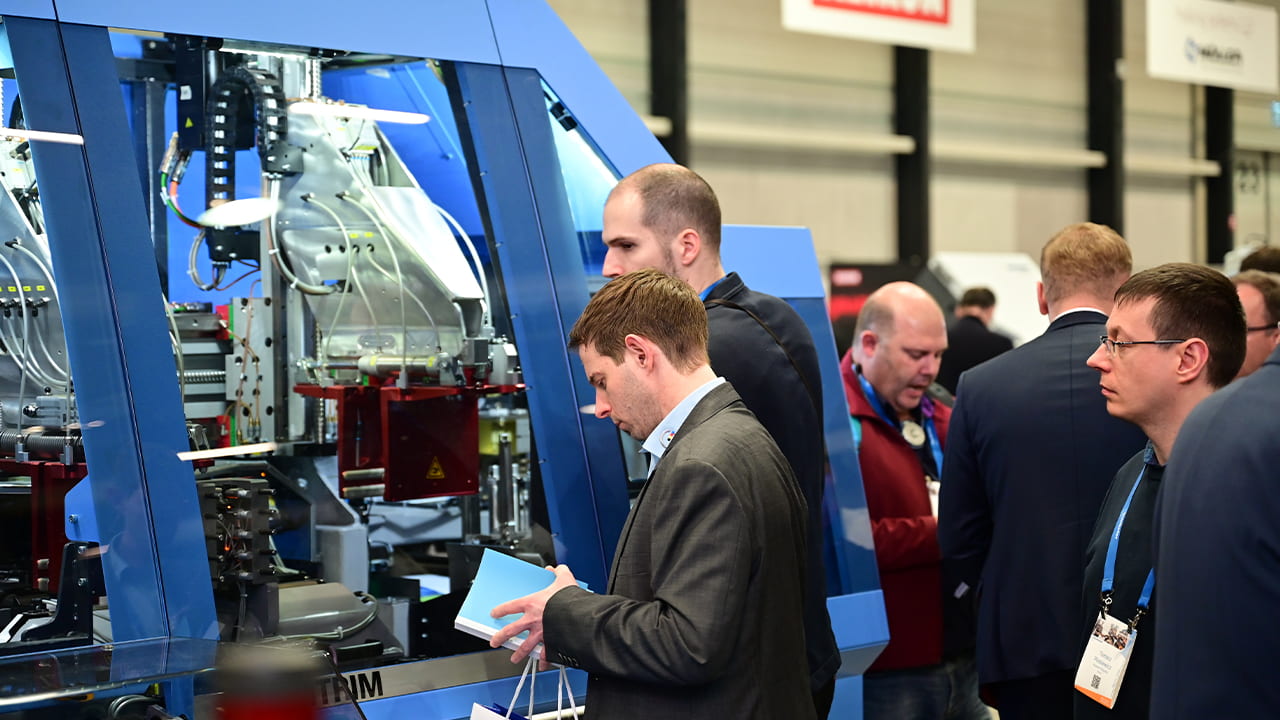

It is precisely such production scenarios that make the Hunkeler Innovationdays so special – it is not individual, isolated solutions that are presented, but networked end-to-end workflows that also demonstrate the application potential. According to the organizers, close to 50 production lines were on display in Lucerne in a wide variety of configuration stages.

The figures give cause for optimism

The figures give cause for optimism

Inkjet printing in particular has made enormous strides in recent years. In terms of quality, it can certainly compare favorably with other digital processes. The print samples on show in Lucerne underline this – and impressive quality can now be achieved even on coated papers.

Many manufacturers point to the expansion of the color space. Canon, for example, speaks in connection with the varionPRINT iX of covering 91 percent of Pantone colors, which is said to be confirmed by FOGRA and Idealliance.

The trend towards inkjet printing can also be seen in the current installation figures, and the forecasts also give cause for optimism. The market is growing for both types of high-speed inkjet systems – web and sheetfed presses. In Europe, new installations of inkjet web presses are expected to grow by around 50 percent between 2021 and 2026. The investment figures for inkjet sheetfed printing systems far exceed this – with 126 percent in Western Europe alone. According to the report "The Future of Print Equipment Markets to 2026" by the market research company Smithers, this trend is expected to continue.

Sheetfed printing systems, especially in conjunction with inline finishing solutions, have a certain charm in that they can produce typical digital printing applications such as short runs extremely efficiently and flexibly. In sheetfed inkjet, Canon is the market leader with the varioPrint iX. Since its launch in 2020, 125 systems have been installed in the EMEA region alone (economic area Europe, Middle East and Africa), with the focus clearly on Europe. Ricoh has been working on a sheetfed system for the B2 format for some time. According to the manufacturer, beta testing has been completed and the market launch is imminent.

Break-even shifts in favor of inkjet printing

With Kodak's new Prosper Ultra 520, the break-even point is said to have shifted significantly. Depending on the product, runs of up to 8,000 copies are realistic, which will accelerate the transformation from offset to digital printing, asserted inkjet veteran Randy D. Vandagriff, senior vice president, digital print at Kodak.

Inkjet was the dominant printing process at Hunkeler Innovationdays. Just two manufacturers were still represented with toner systems. Xerox said that both technologies have their "sweet spot". The exhibitor showed its inkjet ambitions with the inkjet sheetfed printing system "Baltoro". At Xeikon, it was said that not all customers have the corresponding print volume and that toner printing is therefore still an interesting approach, especially in smaller markets.

Mass customization has arrived in the printing industry

Mass customization has arrived in the printing industry

Substrate variety, which used to be a stumbling block for many printers, has also seen some positive developments, and manufacturers have massively expanded their paper profile databases. Print speed is also no longer as much of a focus as it used to be, which should be enough in many cases, especially against the backdrop of further declining run lengths.

Completely different questions arise in order to exploit the efficiency of the systems. These include user-friendliness and the degree of automation, ongoing process and workflow optimization, and service intervals. Ultimately, this determines how economically and profitably the production lines can be used. What always fascinates me is how print products can be produced in run 1 in an industrial digital printing environment. Every book, every folder, every brochure can be completely different in terms of content, size and format. Mass customization" – the adaptation of a mass-produced product to the needs of the individual customer – has thus arrived in the printing industry.

In many discussions at the HID, energy consumption is also mentioned, as this is now a decisive cost factor. Because of the use of water-based inks, there is no way around hot-air drying, and the associated power consumption is something to keep an eye on at current prices. Some manufacturers have taken up the issue. HP, for example, is talking about a significant reduction in energy consumption of around 40 percent for the current PageWide 2200 compared to the predecessor models.

The intrinsic advantages of digital printing

The Hunkeler Innovationdays show once again what a modern data-driven printing industry can look like, what new applications are opening up here and with what efficiency they can be produced in an end-to-end workflow. However, when the print volume is shifted from offset to inkjet printing alone, the intrinsic advantages of digital printing are lost, and these lie not only in print-on-demand production but also in individualization and personalization. If we're smart about it, the Internet will provide us with the data we need.

Yours,

Knud Wassermann,

Editor-in-Chief of "Graphische Revue”

Tomorrow, you can read an HID guest blog by Martina Reinhardt, editor of "Deutscher Drucker".