In the first part of our blog trilogy last week on the subject of sustainability, we discussed the subject of climate change. What does that have to do with the printing industry? Industrial production is responsible for as much as 9 percent of global CO2 emissions – how high is print's share?

According to the

World Resources Institute, the pulp, paper and print industry accounts for around 1 percent of global CO

2 emissions. By comparison, all digital technologies (networks, computers, tablets, cell phones) together cause about as many emissions as all of Germany. Some 4 percent of global emissions are made up by our digital infrastructure, with an increasing tendency.

The largest share of the CO

2 footprint of print products is attributable to substrate production. Depending on which substrate is used (and who you ask), the proportion of substrate is between 55% and 80%.

This is not a major surprise, as the paper industry is one of the most energy-intensive industries and is therefore in the same category as the glass and steel industry. It is obvious why this is the case. Production consumes lots of water, heat and mechanical energy. It certainly causes you to sweat. Anyone who has ever been in a paper mill will know what I mean.

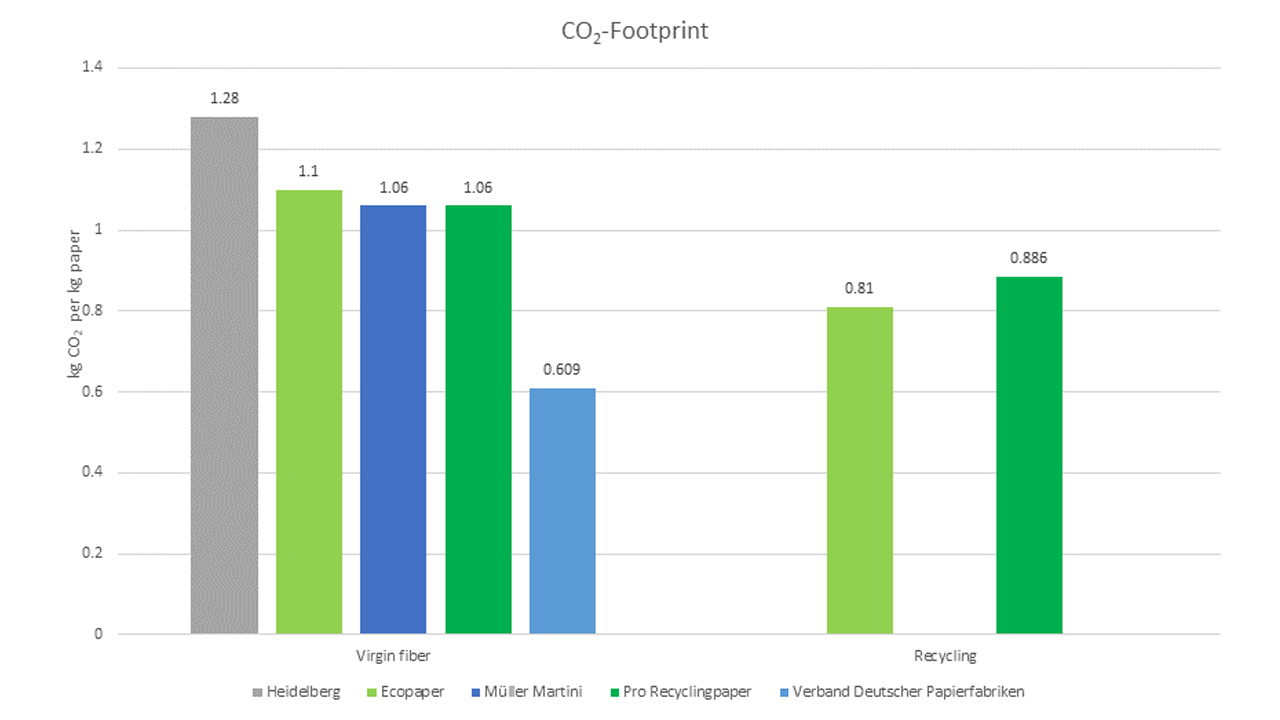

How much CO2 does 1 kg of paper cause?

Heidelberg states in its

“Solutions for an environmentally friendly printing process” report that one kilogram of paper causes 1.28 kg of CO

2 in production. This data refers to the results of the ecoinvent database and applies to coated sheet-fed offset paper.

The Swiss association

Ecopaper, which also bases its results on the ecoinvent database, states a value of 1.10 kg of CO

2 in its paper calculator for one kilogram of fresh fiber paper. For recycled paper, the value is 0.81 kg CO

2.

Muller Martini arrives at similar

figures. The Swiss machine manufacturer states a value of 1.06 kg CO

2 for the production of one kilogram of fresh fiber paper. This value also matches the data of the Initiative Pro Recyclingpapier's sustainability calculator. For recycled paper, the Initiative states a value of 0.886 kg CO

2.

Germany's federal government figures put average CO

2 emissions for one kilogram of paper at 0.609 kg of CO

2 . It arrives at this figure on the basis of data from the Association of German Paper Mills and states that this matches the figures from emissions trading.

Major difference between types of paper

However, this figure seems somewhat unrealistic and will likely relate to the totality of all paper products, i.e. to cardboard packaging or sanitary papers. The truth is likely somewhere between these values. The footprint varies strongly between the types of paper and depends on the share of recycling fibers.

The origin of the raw materials also has a strong impact on the CO

2 footprint. After all, the transport route makes a crucial contribution to how many emissions are caused. Whether the raw material of wood or in many cases already fiber (or pulp) needs to be transported for thousands of kilometers, of course, changes the value by several orders of magnitude.

Processing accounts for about 13 percent

Processing accounts for about 13 percent

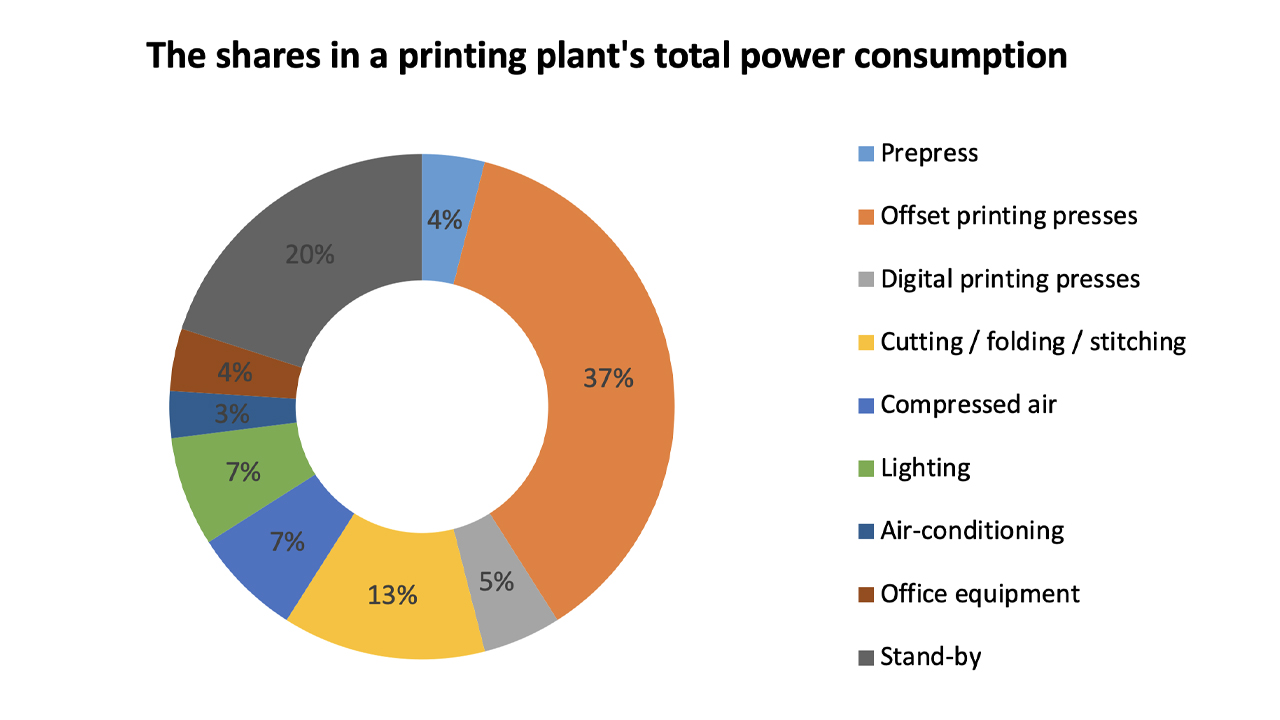

Printing and processing machines make only a small contribution to a product's CO

2 footprint. Print finishing, in particular, requires energy as the sole means for production. A printing plant's power consumption is therefore the second largest source of emissions. The second largest one here, however, is 10 to 20 percent of the emissions.

According to the

Umweltdruckerei, of these 10 to 20 percent, 37 percent are made up by offset printing presses and 5 percent by digital printing presses. Print finishing of products contributes some 13 percent through cutting, folding and stitching. Another factor having an impact is the consumption of compressed air. Almost every machine in this area of production requires this costly energy to move pneumatically driven parts or separate signatures. The Umweltdruckerei states that the proportion of compressed air is around 7 percent.

Muller Martini's position

Muller Martini conducted in-house investigations into energy consumption some time ago – and came up with several interesting findings. The electric energy consumption of a print finishing machine increases in a linear fashion with the speed of the machine. In addition, a machine consumes only about 10 percent more energy when operating compared to when it is idling. This means that as production speeds increase, the electric energy requirement (and thus CO

2 emissions) per copy decreases.

As a result, the typical electric energy requirement caused by print finishing of, for example, 1,000 products in saddle stitching is only about 1 kilowatt hour.

On the topic of compressed air consumption: it is highly dependent on the user settings for suction and blow air, which – if you think about it – also makes sense.

Saddle stitchers also create the greatest blow air consumption by separating and opening signatures.

When considering all this information together, Muller Martini states the energy requirement share of further processing at around 2 to 3 percent for a product, which roughly matches my findings.

Some calculation examples

I have now tried to create a rough CO

2 footprint for a print product with these figures. Let us take a softcover book in DIN A5 format.

It has a volume of 402 pages and the paper a grammage of 100 g/m

2, whereas the cover has a grammage of 200 g/m

2.

After some rule of three and conversion, our sample brochure comes in at about 630 g. Let us now assume that the paper for the book block corresponds to the normal paper mix with a recycled paper share and the cover is a nicely coated glossy paper made from fresh fiber. If we now use the above values of Initiative Ecopaper and Pro Recyclingpaper, we arrive at a value for the CO

2 emissions of the paper. As we have already established that paper manufacturing makes up about 80 percent of the emissions when making printed material, we can therefore estimate how much the rest will be. Ultimately, we arrive at a quite precise value of 1 kg of CO

2 for our sample book.

When searching for comparison values, a study of the Freiburg-based Öko-Institut keeps popping up. It has calculated that about 1.1 kilograms of CO

2 are required for the production of a book with 200 DIN A5 sheets and 135 g/m

2, which consists solely of fresh fiber paper. If I adjust the values in my calculation accordingly, I arrive at the same result. However, I consider such a high grammage to be excessive for a normal book.

Fluctuations due to different volumes

A similar calculation can be found on the

www.printintelligent.de website. It arrives at CO

2 emissions of 1.36 kg per book, but also assumes slightly different parameters. I also arrive at this result with the same configurations for the book.

This small example already shows the following: the CO

2 emissions fluctuate very strongly in line with the volume of the product because the majority is made up by the paper, as we already know. They also include the production-related emissions, of course. If a report from the

Süddeutsche Zeitung is believed, shipping the parcel via DHL generates about 500 g of CO

2.

The final result is therefore 1.5 kg of CO

2. This means that I am almost exactly in the average range of all values that I could find on this subject. The sole dissenter of this magnitude is the Babcock School of Business, which states some 10.2 kg of CO

2 emissions for a book. However, a weight of 2.18 kg was assumed in their calculations, which I consider to be a lot. The details for this calculation were unfortunately not available, which is why I cannot verify this calculation.

Next Tuesday, in the third and final part of our sustainability blog series, find out whether the digital alternatives are really as green as many think.

Your

Arne Klages

Arne Klages is a student at the Stuttgart Media University in Germany. He has been taking the relatively new Print Media Technologies course toward a Bachelor of Engineering degree since 2018. Before that he trained as a Print Media Technician, where he developed an interest in all things related to print.